In the aerospace sector, safety, reliability, and performance hinge on the utmost precision and leak-tightness of every component. From aircraft engines to satellite systems, the demand for flawless engineering is non-negotiable. Tactile supports this mission by delivering advanced vacuum technologies and high-purity manufacturing solutions that meet the industry's strictest standards.

Aerospace

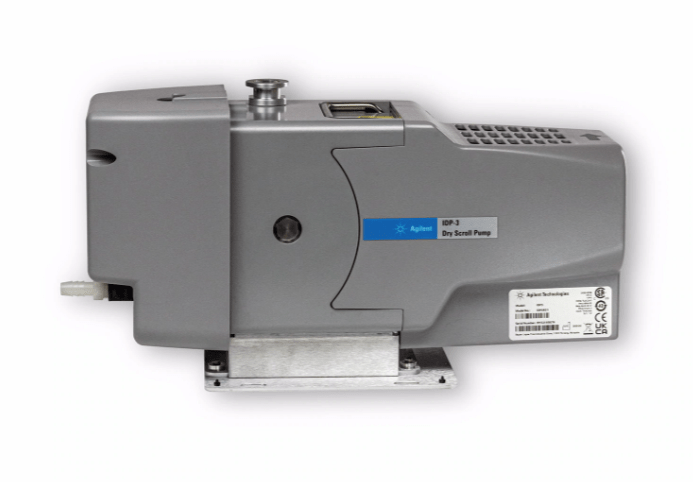

Aerospace manufacturers rely heavily on cutting-edge vacuum-based processes such as electron beam welding (EBW) and electron beam melting (EBM) to produce mission-critical components like turbine blades and propulsion system elements. These processes, ensure minimal contamination, superior material integrity, and exceptional bonding strength.

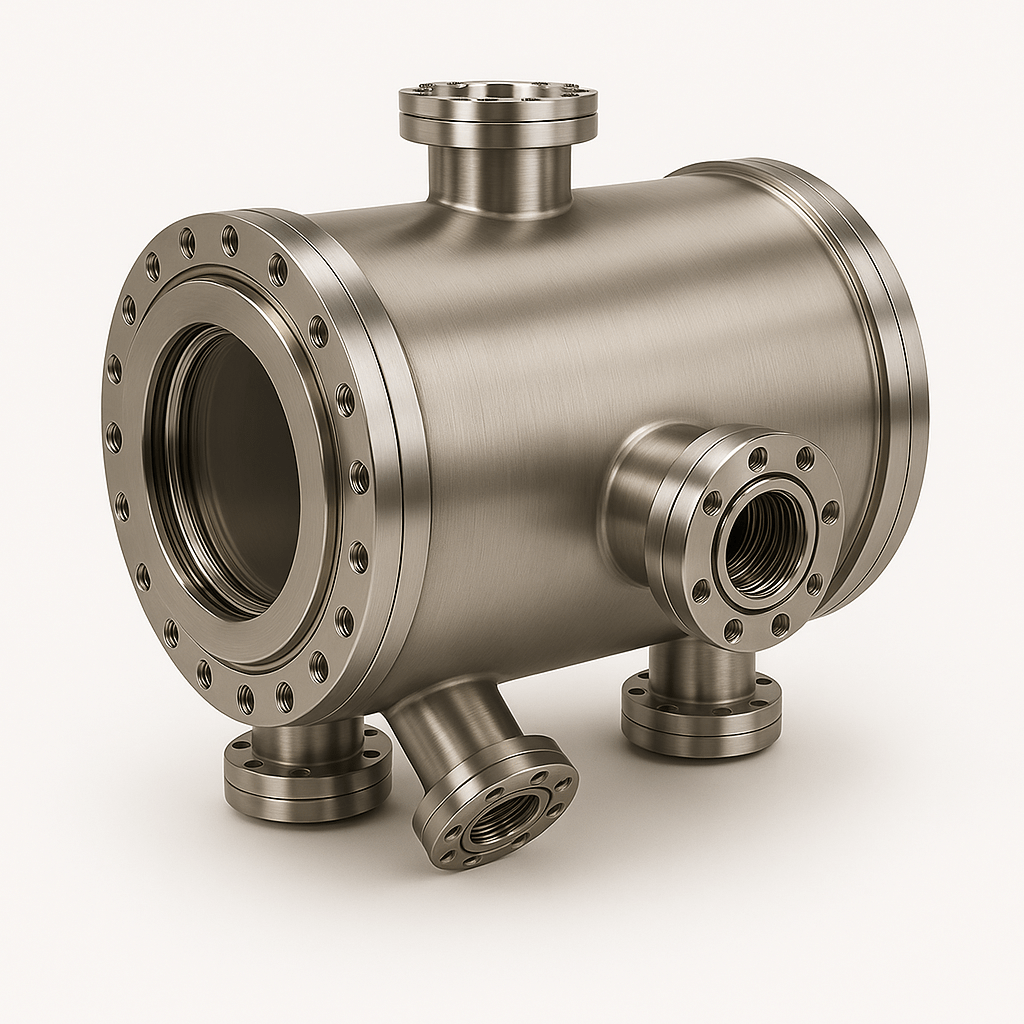

Tactile’s large-scale vacuum chambers are also integral to the development and validation of aerospace systems. These chambers replicate space-like conditions—extreme vacuum, thermal cycling, and radiation exposure—to rigorously test satellites, engines, and structural assemblies before launch, reducing risk and increasing mission success rates.

As the aerospace industry shifts toward cleaner, more sustainable technologies, Tactile is at the forefront of supporting this transition. Our solutions enable the fabrication of lightweight materials, support low-emission propulsion systems like electric and hydrogen engines, and facilitate ultra-clean environments for high-purity processing. By integrating advanced clean technologies into aerospace manufacturing, Tactile helps clients meet both performance goals and environmental mandates.

With deep expertise in vacuum science and a commitment to innovation, Tactile empowers aerospace pioneers to achieve safer, greener, and more advanced missions—both on Earth and beyond.