Engineering Sputtering Targets for Process Predictability

Expertise

In vacuum sputtering, thin-film performance is only as stable as the target material supplying it. While engineers often focus on recipes, power, and tool configuration, many persistent yield and repeatability problems originate inside the sputtering target itself.

The goal is not optimization.

It is predictability.

What Engineers Are Trying to Achieve

Engineers working with sputtering systems want:

- Stable deposition rates

- Uniform films within specification

- Minimal defects and downtime

- Confidence in repeatability

These goals are universal across semiconductors, displays, optics, energy, and R&D.

Why Sputtering Becomes Unpredictable

Sputtering is a direct material-transfer process. Any instability in the target transfers directly into the process. Variations show up as plasma instability, film drift, particle generation, and ultimately reduced yield and uptime.

The most common root causes are material-related, not process errors:

- Non-uniform grain size

- Trace impurities that concentrate rather than average out

- Phase segregation in alloys or compounds

- Thermal stress and cracking

- Poor bonding or CTE mismatch between target and backing plate

The Hidden Cost of Compensating

When target behavior is treated as a given rather than a variable to be engineered, processes begin to compensate instead of stabilize. Recipes grow complex. Process windows narrow. Variability becomes accepted rather than solved.

Over time, instability compounds, making control harder with every iteration.

A Different Approach: Engineer the Target

Stability is restored by addressing:

- Grain size and uniformity

- Purity beyond headline percentages

- Density and microstructure

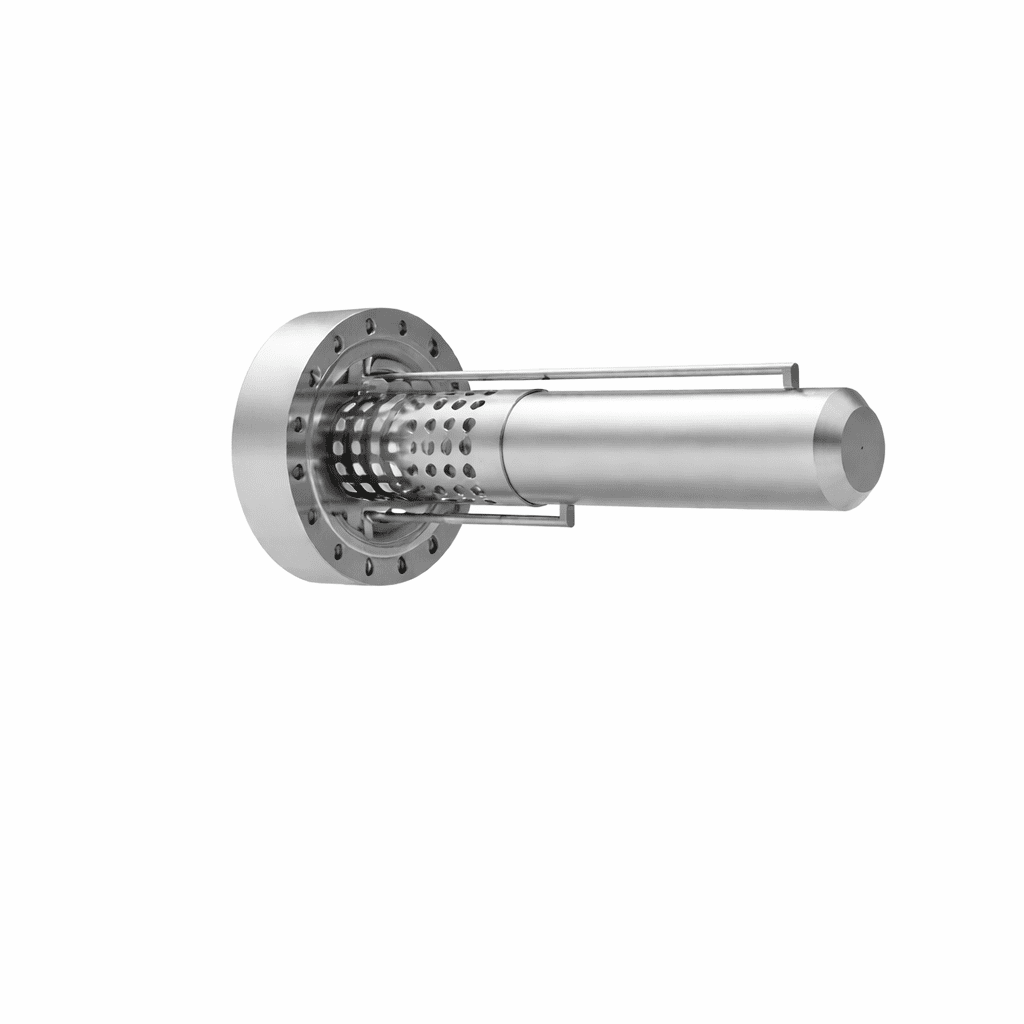

- Thermal and mechanical design

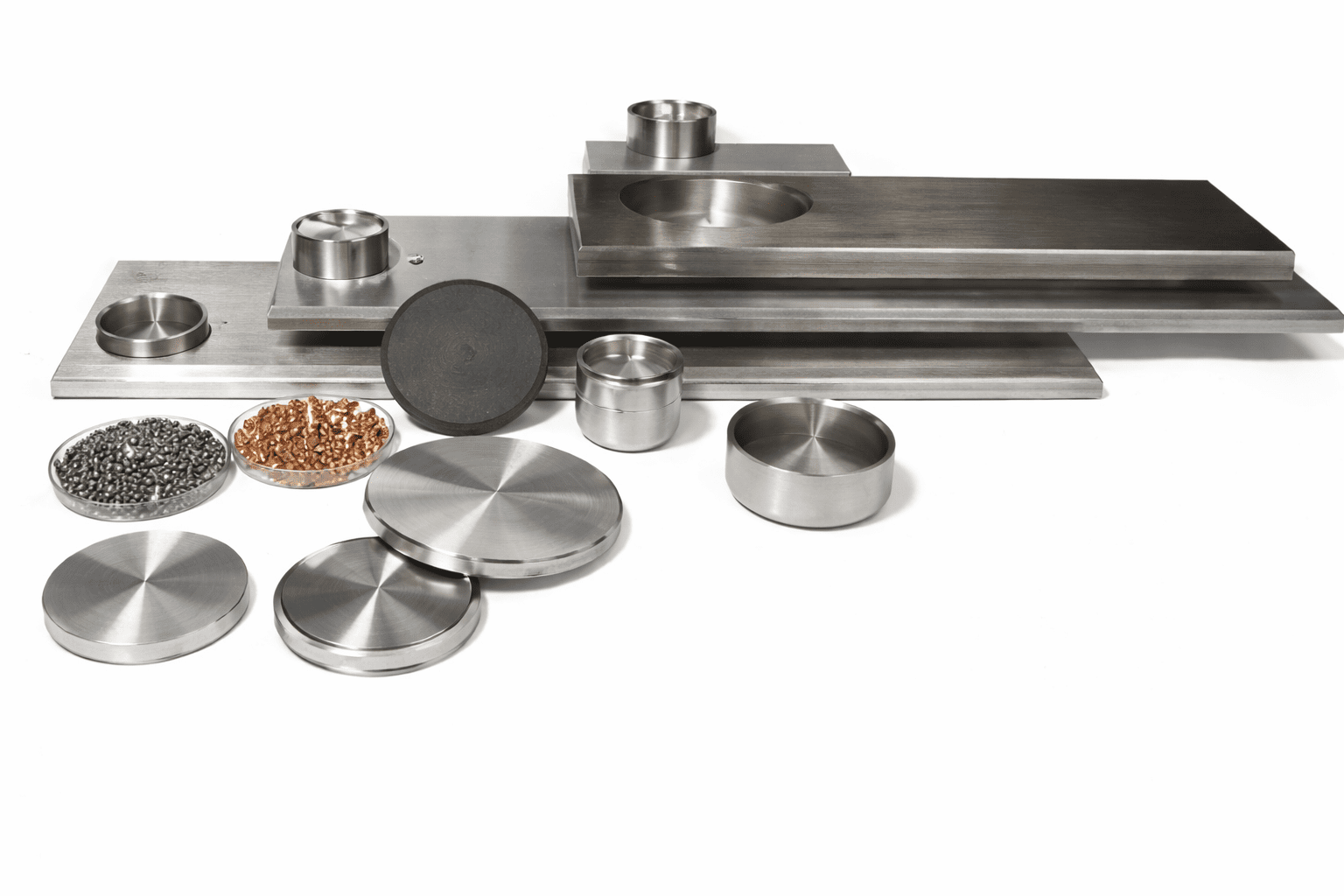

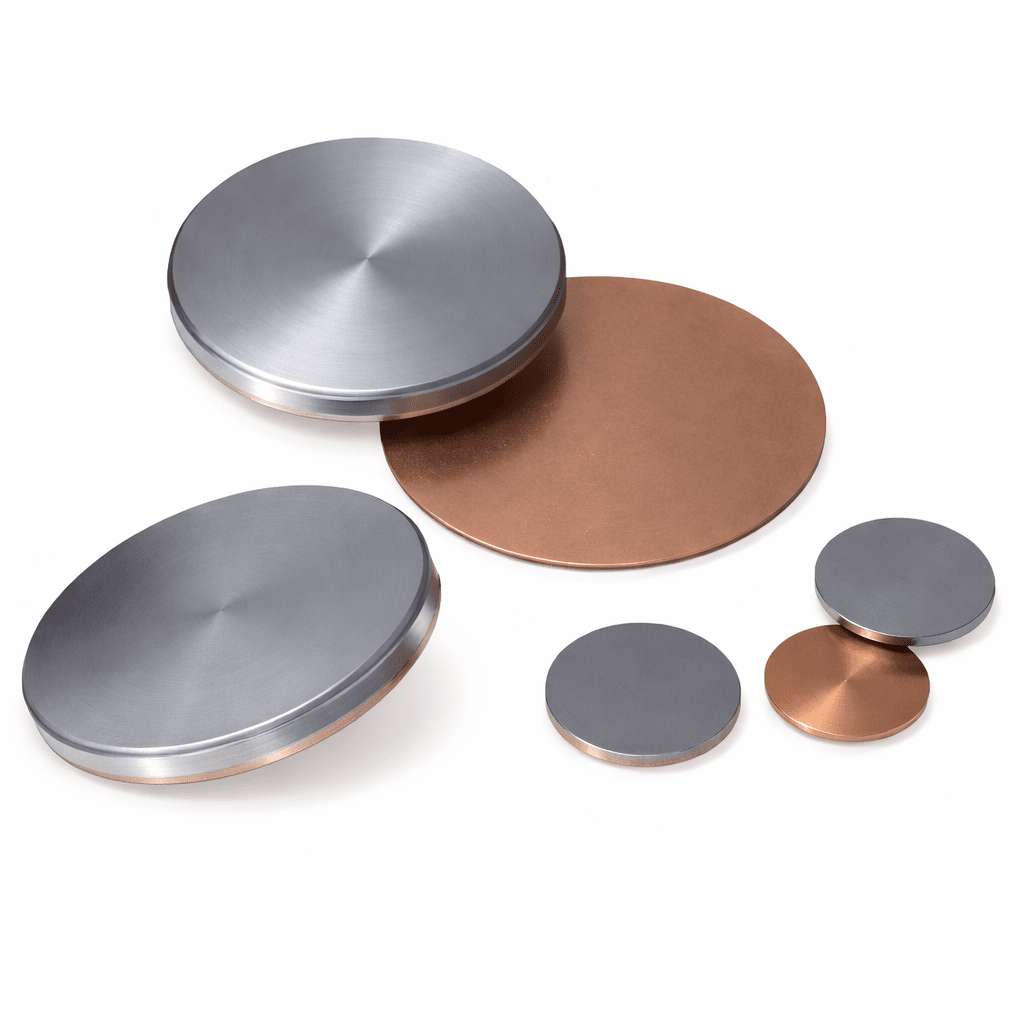

- Bonding and backing plate selection

This is not theoretical. It is practical risk reduction.

The Path to Stability

A structured approach removes uncertainty:

- Clarify requirements

- Confirm critical specifications

- Select appropriate manufacturing routes

- Deliver targets ready for predictable use

What Success Looks Like

The process stabilizes. Deposition repeats run-to-run. Films stay within control limits. Arcing, particles, and drift decrease. Target lifetime aligns with planning instead of surprise failures.

Internally, confidence returns. Qualification cycles shorten. Stress drops. Engineers trust the process because it behaves like an engineered system, not a gamble.

In sputtering, winning is not chasing perfection, it is removing uncertainty.

When the target is engineered, not assumed, processes stabilize, results repeat, and progress becomes controlled.

Request a quote at info@tactile.tools or Start My Target Specification Sputtering Targets | Planar & Rotary Thin Film Materials for PVD Deposition