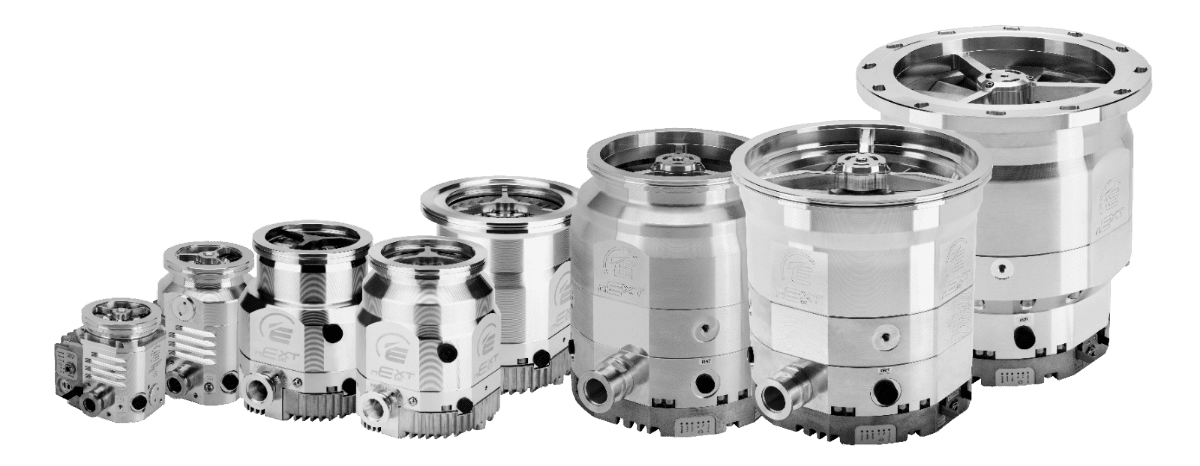

Turbomolecular Pumps for High & Ultra-High Vacuum

Product news

The issue is hidden risk: backing pumps mismatched, sensitivity to particulates or air inrush, and vibration that quietly erodes data quality and uptime.

It shouldn’t be this hard, high and ultra-high vacuum should be predictable, not a balancing act.

The plan is clear: (1) define your target pressure and gas load, (2) select the right turbomolecular architecture: mechanical, hybrid, or maglev, (3) pair it with a properly sized backing pump and protection strategy.

Because turbomolecular pumps transfer momentum at high speed, correct integration protects the rotor, stabilizes foreline pressure, and preserves oil-free cleanliness.

Follow this approach and you gain lower noise, lower vibration, faster pump-down, and confidence that your system performs as specified.

You spend less time troubleshooting and more time delivering results that stand up to review.

We define your requirements upfront and take a technology-first approach, selecting pumps to fit your system, not a brand, while providing full transparency on assumptions, timelines, and expectations. You remain in complete control with no pressure to proceed, and nothing moves forward without your approval.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Get a quote at info@tacile.tools or Define My Turbomolecular Pump