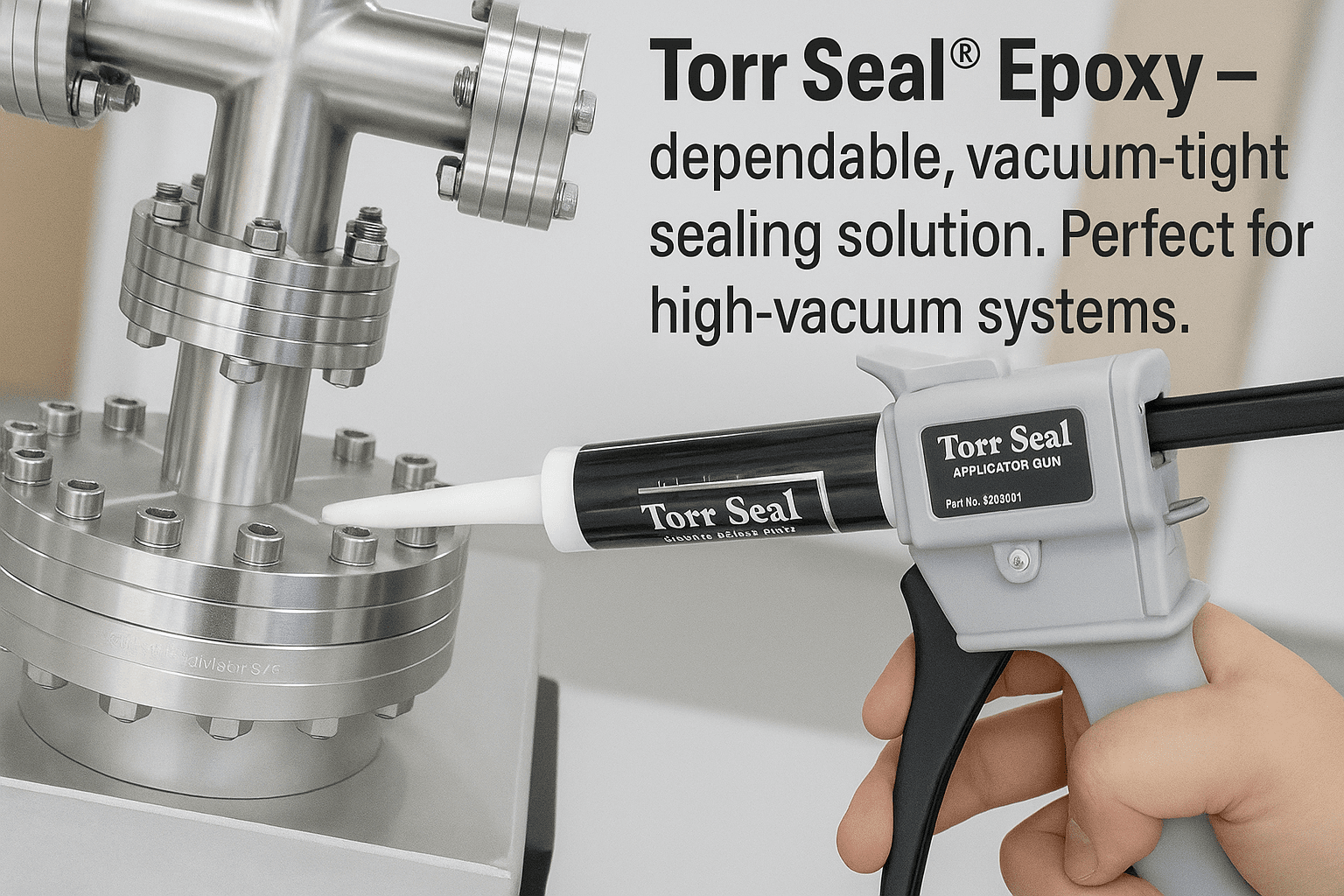

Consumables: Torr Seal in Vacuum Systems

Product news

You want a vacuum seal you can trust, one that holds under high vacuum without leaks, rework, or downtime, but improper epoxy use often puts that reliability at risk.

The tension lies between needing a fast fix and knowing that rushed mixing, poor surface prep, or early pump-down can compromise your entire system.

The real problems is impatience and uncertainty: externally from demanding schedules, internally from underestimating how precise vacuum sealing needs to be—and it shouldn’t feel this fragile.

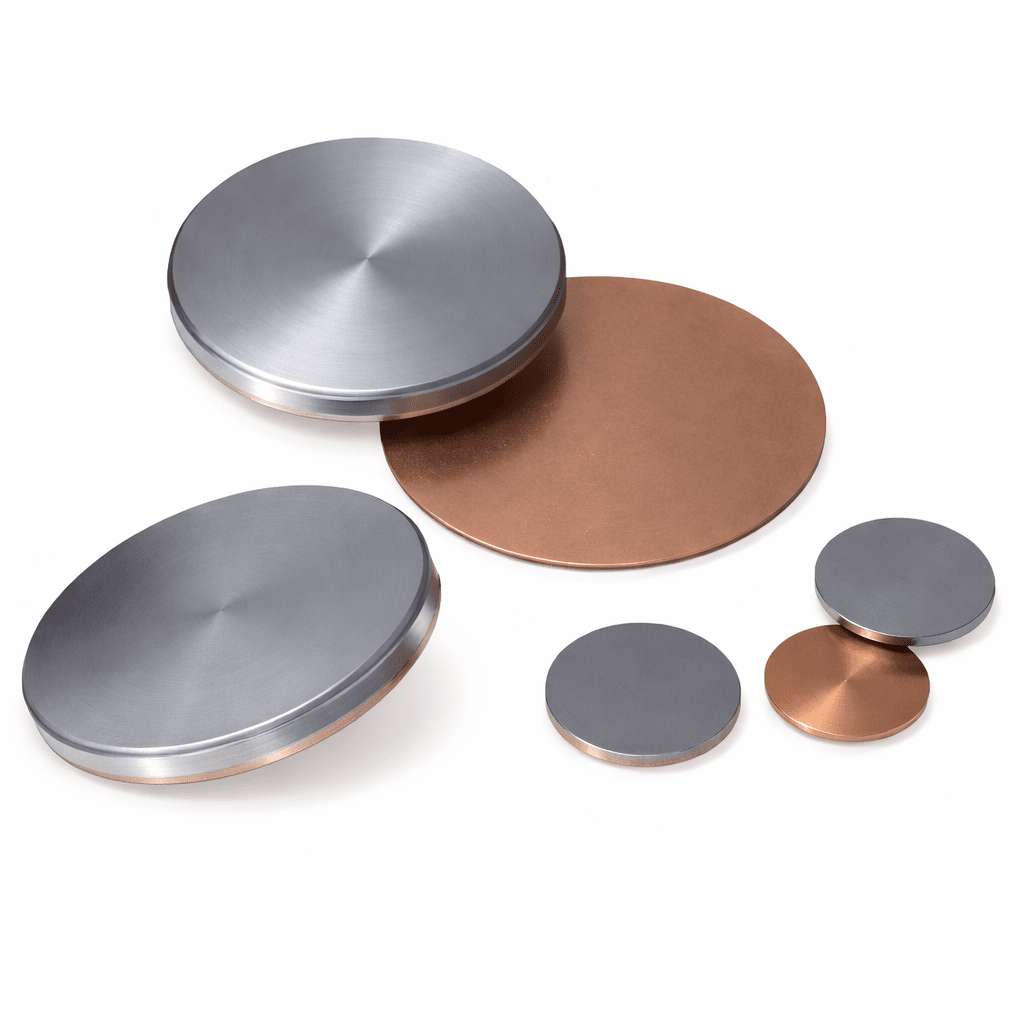

The solution is a simple, disciplined plan: prepare surfaces until they are clean, dry, and grease-free; confirm you are bonding compatible materials like metals, glass, or ceramics; and mix Torr Seal resin and hardener accurately and thoroughly.

Apply only small batches, avoid trapped air, and allow the bond to develop handling strength before stressing the joint.

Give the epoxy time to fully cure, hours for function, days for performance, so outgassing drops and long-term stability increases.

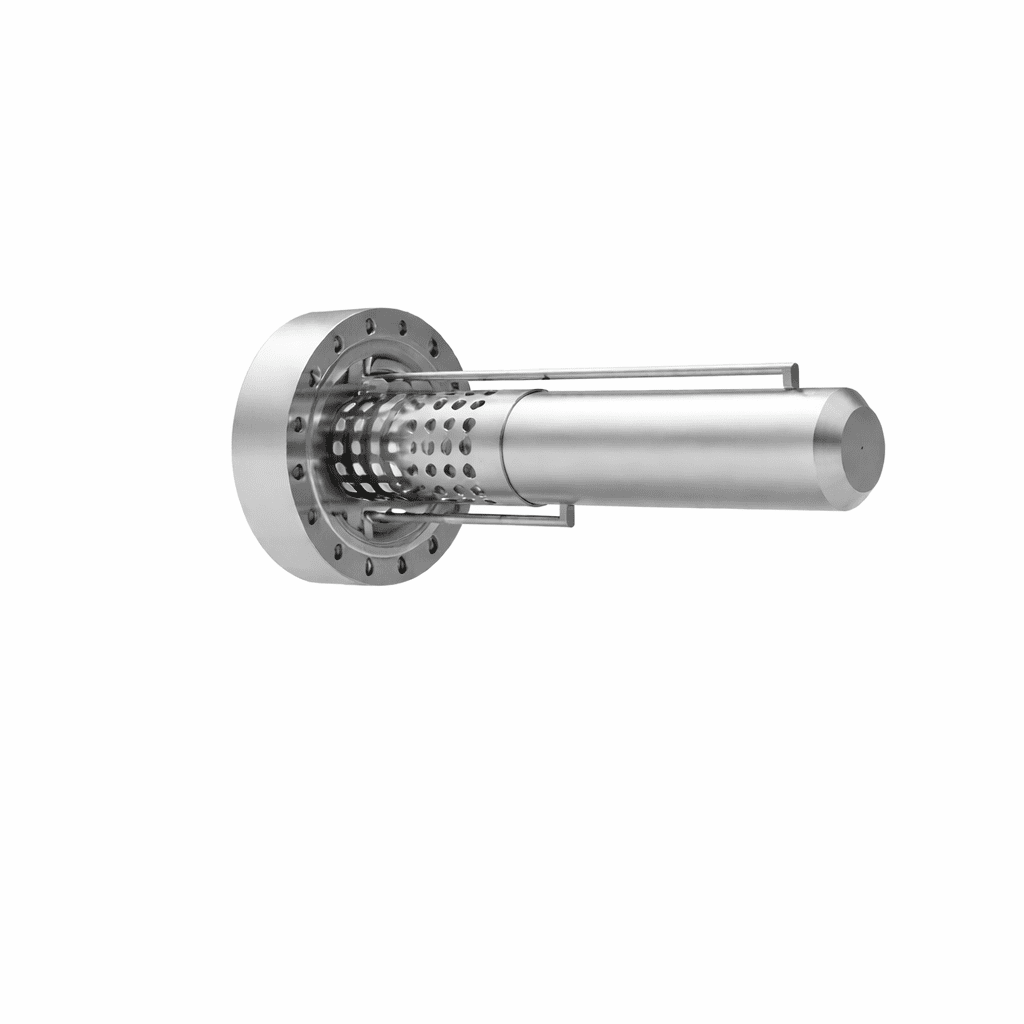

When done right, Torr Seal delivers bakeable, low-outgassing seals down to 10⁻⁹ Torr, fewer leaks, and far less troubleshooting.

You gain confidence, reduced pump downtime, and the calm assurance that your vacuum system will perform as designed.

Follow this method and move forward with a vacuum seal that lasts instead of one you have to fix.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Request a Quote at info@tactile.tools or learn more Tactile | Tools for Advanced Clean Tech - Advice