A Guide to Sputtering Target Material Groups

Expertise

As an engineer or materials specialist, you aim to create thin films that meet exacting performance standards. You want reliable deposition processes and high-quality coatings that give your products a competitive edge. Whether you’re developing advanced semiconductor devices, durable optical coatings, or high-density storage media, your goal is clear: achieve the best film properties with minimal hassle and downtime. You need sputtering targets that consistently deliver the right material properties so you can focus on innovation and results, not on troubleshooting materials issues.

Selecting the ideal sputtering target material can be overwhelming and risky. There are numerous material groups to choose from, pure metals, alloys, ceramics, composites, each with its own strengths and applications. It’s frustrating when technical jargon and complex options make it hard to decide which target will fulfill your specific requirements. If you choose the wrong material or purity level, you could face problems like impure films, poor adhesion, premature target wear, or underperforming devices. In a fast-paced engineering environment, you don’t have time or budget to waste on trial and error. You need clarity and confidence in your target material choice to avoid costly setbacks and ensure your project’s success.

We understand how critical these decisions are for you. With years of experience in thin-film deposition, our team has guided countless engineers through the maze of sputtering material options. We position ourselves as your reliable guide, a partner who not only understands every facet of sputtering targets but also puts your needs first. We’re here to simplify the process and share our expertise so you can make an informed choice with confidence.

Our Expertise: We have deep knowledge of all common sputtering target material groups and maintain a comprehensive catalogue of options. This means we can objectively recommend what’s best for your application, rather than pushing a one-size-fits-all solution. We won’t confuse you with unnecessary jargon or boast about ourselves. Instead, we focus on answering your questions, explaining options in clear terms, and backing up our guidance with proven performance data.

Sputtering Target Material Categories: Over the years, we’ve worked with every major type of sputtering target. Here are the five key material groups we can help you navigate, each engineered for specific needs:

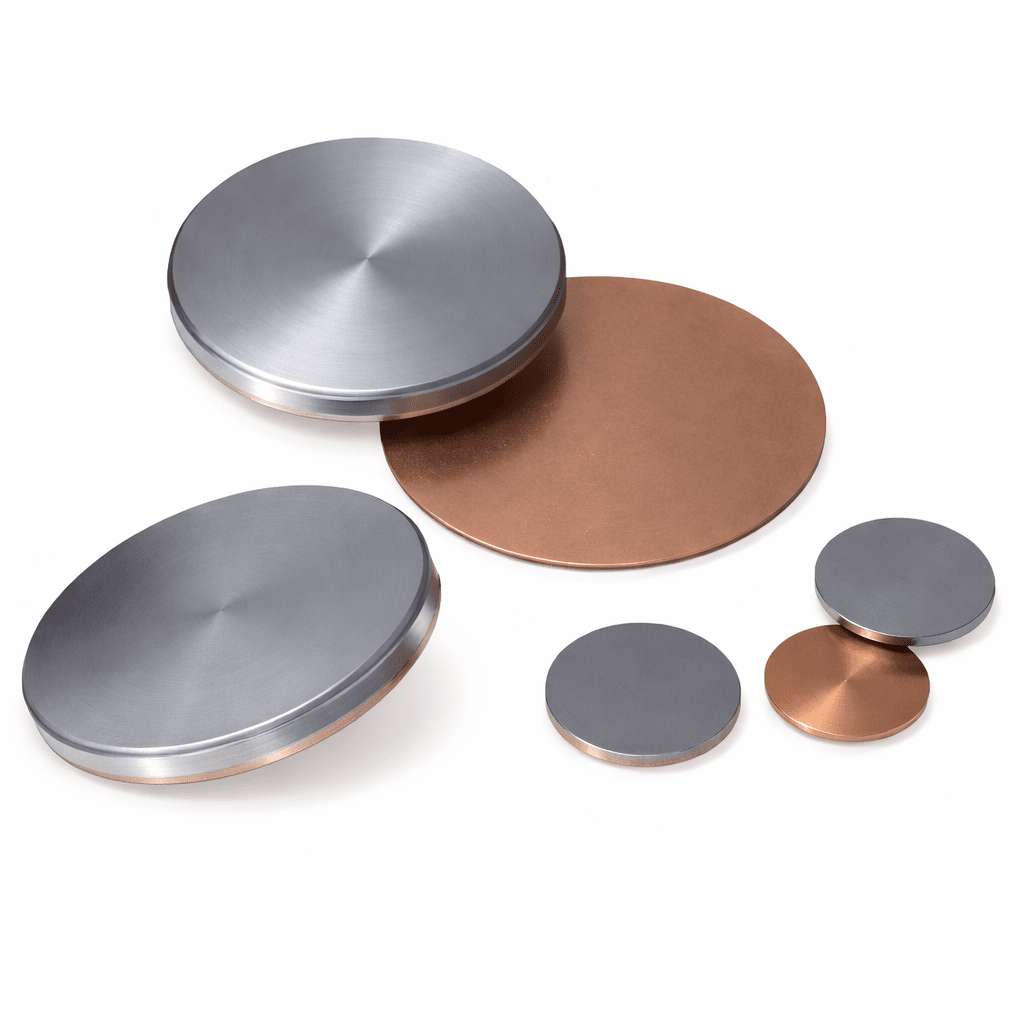

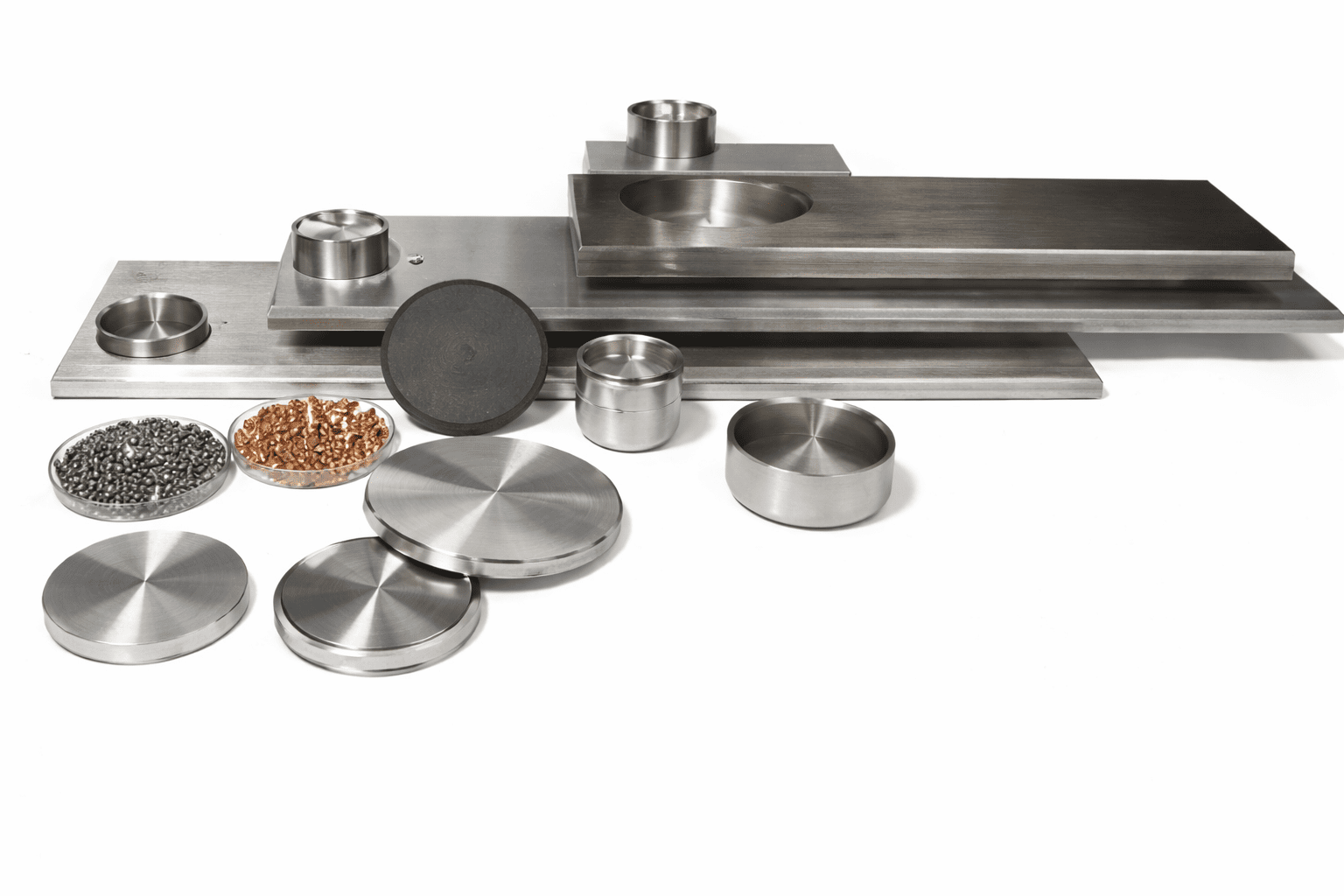

- Metal Targets (Pure Metals & Alloys): These are high-purity elemental metals or metal alloys. Metal targets offer excellent electrical and thermal conductivity, making them ideal for uniform, high-rate deposition. Common examples include aluminium (for reflective coatings and IC interconnects), copper (for high-conductivity wiring layers), titanium (for strong, corrosion-resistant barrier films), and chromium (for hard protective coatings). We provide metals in a range of compositions, from single elements to advanced alloys, all processed for high density and fine grain structure to ensure consistent sputtering performance. Metal targets are the workhorses for electronics, optics, and decorative coatings, and we ensure they meet ultra-clean purity standards (up to 99.9999%, in many cases) for defect-free films.

- CerMet Targets (Ceramic–Metal Composites): CerMet sputtering targets combine the hardness and thermal stability of ceramics with the toughness and conductivity of metals. These composite targets are ideal when you need a film that is both durable and functional. For example, solar selective absorber coatings often use cermet targets like tungsten–aluminum nitride, which yield films with high solar absorption and low thermal emittance for efficient solar thermal panels. Similarly, titanium carbonitride cermet targets (with a nickel or cobalt binder) produce extremely hard, wear-resistant coatings used on cutting tools and decorative hardware. By hot-pressing ceramic powders (like TiC, TiN, or Al₂O₃) with metal binders, we achieve a uniform composite that sputters smoothly. The result is a thin film that benefits from the best of both worlds, ceramic durability and metal-like conductivity, tailored for specialized applications such as wear-resistant surfaces, sensors, and even fuel cell electrodes.

- Inorganic Compound Targets (Ceramics): When pure metals can’t deliver the specialized properties you need, inorganic compound targets step in. These are ceramic materials such as oxides, nitrides, carbides, and other advanced compounds. They enable thin films with unique optical, electrical, or mechanical properties: for instance, indium tin oxide (ITO) targets deposit transparent conductive films indispensable for touchscreens and solar cells, while aluminium nitride or silicon nitride targets yield hard, insulating films for electronics and wear components. We densify our ceramic targets using techniques like hot isostatic pressing to ensure they sputter stably (brittle targets won’t crumble on you). Whether you require oxide targets (Al₂O₃ for insulating layers, TiO₂ for anti-reflective coatings), nitride targets (TiN or ZrN for ultra-hard protective films and decorative gold-tone coatings), carbide targets (like SiC or WC for extreme hardness and high-temperature resilience), or even specialty compounds (such as lithium-containing ceramics for battery thin films), we have you covered. These inorganic targets allow you to achieve films with extreme hardness, high thermal stability, chemical resistance, or precise electronic properties that metal films alone cannot provide.

- Complex Composite Targets: For next-generation technologies, we offer complex sputtering targets that contain a finely tuned mix of metal and non-metal phases. These targets deposit multi-phase thin films with controlled nano-structures, critical in applications like magnetic data storage and advanced sensors. A prime example is the granular magnetic films used in today’s highest-capacity hard drives: a complex target might consist of a magnetic alloy (such as iron–platinum or cobalt–chromium–platinum) intimately mixed with an oxide like silicon dioxide or magnesium oxide. During sputtering, this yields a film where tiny metal grains are each insulated by an oxide boundary – a structure that dramatically reduces magnetic noise and enables higher storage density. If you’re working on Heat-Assisted Magnetic Recording (HAMR) media or spintronic devices like MRAM, these composite targets are the key to success. They are challenging to manufacture (we use advanced powder metallurgy to disperse phases uniformly and bond the target to a copper backing plate for durability), but our expertise ensures you get a target that performs reliably. In short, complex composite targets empower you to deposit cutting-edge functional films – from ultra-dense magnetic layers to high-sensitivity GMR sensor stacks – with confidence in the material’s consistency.

- Ultra-High-Purity Metal Targets: In semiconductor fabrication, aerospace, or any application where every impurity could mean failure, high-purity sputtering targets are a must. We specialize in ultra-pure metals, offering targets refined to purity levels of 5N to 6N for the most demanding processes. Using a high-purity target means your deposited films have minimal contamination and defect levels, which translates to better electrical performance and higher device yields. For example, we can supply aluminium and copper targets at 6N purity, perfect for semiconductor interconnects and transparent electrode films, as well as ultra-pure titanium, indium, tin, and others for microelectronics and optical coatings. By choosing an ultra-clean target, you reduce variability in your process and ensure that nothing but the intended material is going onto your substrate. The benefit to you is a more stable sputtering process, repeatable results, and peace of mind that your thin films will meet the strictest quality standards.

A Clear Plan for Your Success

Uncertainty is the enemy of progress. To remove any risk and make your path to success straightforward, we follow a simple 3-step plan with you:

- Schedule a Consultation: First, reach out and tell us about your project’s goals and challenges. We’ll listen carefully as you describe your application (what thin film you need, what properties matter most, any issues you’ve faced). Our experts speak your language, whether it’s about achieving a certain hardness, electrical resistivity, optical transparency, or deposition rate, and will ensure we fully understand your requirements. (You can easily schedule a call or send us an inquiry online to get started.)

- Get a Tailored Material Recommendation: Next, we analyze your needs and guide you to the ideal sputtering target material group and composition. This is where our broad experience truly benefits you. Based on the information you provide, we will identify which material category (metal, cermet, ceramic, composite, or high-purity metal) best suits your objectives. Then we narrow down the exact target material or alloy and purity that will give you the performance you’re looking for. You’ll receive a clear explanation for our recommendation – no guesswork needed on your part. We’ll outline how this choice addresses your challenges (for example, recommending a cermet target if you need a combination of hardness and conductivity, or suggesting a 6N pure metal if contamination is a concern). This step removes the uncertainty and risk from the decision. You’ll have a concrete plan for which sputtering target to use and why.

- Succeed in Your Deposition Process: Finally, we deliver your chosen sputtering target and support you through implementation. Our manufacturing team will provide a high-quality target (bonded to backing plates if needed, tested for purity and density) so it arrives ready to perform. We stand behind our products, so if you have any questions during setup or deposition, our technical support is on hand. With the right target in your system, you can proceed confidently with deposition. The result? You achieve the thin-film characteristics you set out for – whether it’s a perfectly conductive copper layer, a razor-hard nitride coating, or an ultra-dense magnetic film. We check in to ensure everything is running smoothly. Your success is our success, and we make sure the plan is executed to your satisfaction.

This plan lays out every step on the path to thin-film success, removing ambiguity and giving you a clear roadmap. By following these steps, you drastically reduce the trial-and-error that typically slows projects down. Instead, you move forward with a trusted material and a team of experts backing you up.

Take the Next Step

We invite you to schedule a call with our sputtering materials experts today, ask us anything, and let’s discuss how to achieve your thin-film goals. If you’re ready for a quote or have a specific material in mind, request a personalized quote and we’ll respond promptly with details.

We’re here to help you move forward and make your project a success, but the first step is yours to take. Reach out today and put our expertise to work for you.

Picture this: in the near future, you’re running your deposition process with zero headaches. The sputtering target you chose (with our guidance) is performing flawlessly, uniform film thickness, the exact material properties you needed, and no unexpected contaminants or defects. Your thin films are elevating the performance of your product or research project beyond expectations.

You can focus on innovation and productivity, knowing that your coatings are reliable and your process is optimized. Your team works more efficiently, and you might even finish the project ahead of schedule because there were no material-related delays. By making an informed choice and partnering with a trusted guide, you’ve removed a major uncertainty from your project.

Ready to experience this kind of success? It starts with choosing the right sputtering target material. Let us help you make that choice, and join the many engineers who have achieved superior thin films with a little guidance.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Request a quote at info@tactile.tools or Start My Target Specification Sputtering Targets | Planar & Rotary Thin Film Materials for PVD Deposition