RGA: How to Understand Vacuum Problems Without Guesswork

Case Studies

When gas composition remains invisible, the same issues tend to repeat. Results degrade despite acceptable pressure. Bakeout and pump down endpoints are chosen by habit instead of data. Small contamination events go unnoticed until damage is done. Over time, this makes it harder to trust the system and move forward with confidence.

The good news is that this problem does not require more procedures or tighter rules. What engineers actually need is clear insight into which gases are present, not just how much gas there is. Think of it like checking the contents of a container instead of only weighing it. The weight alone does not tell you what is inside.

A Simple Way to Fix the Problem

- Step 1 Clarify What You Need to Understand

Decide whether the goal is leak detection, outgassing analysis, contamination identification, bakeout confirmation, or process monitoring. This keeps the solution focused on outcomes, not instruments.

- Step 2 Understand Where the Measurement Will Operate

Identify base pressure, operating pressure, pressure excursions, and whether gases are static or flowing. This prevents damage and ensures reliable measurements.

- Step 3 Match the Measurement to the Gas Chemistry

List expected gases such as hydrogen, water, air components, hydrocarbons, or reactive species. This ensures the data is meaningful and the system survives real conditions.

- Step 4 Right Size Performance

Choose only the mass range, sensitivity, and scan speed needed for the job. More performance is not always better if it adds complexity without value.

Before this approach, teams often feel:

- Unsure why results drift

- Stuck debating causes without evidence

After applying these steps, they experience:

- Clear separation of leaks, outgassing, and contamination

- Confident decisions backed by gas composition data

This is where uncertainty turns into control.

By supporting engineers through goal definition, vacuum reality, gas chemistry, and practical constraints, Tactile supports the clarity described above without adding unnecessary complexity.

If you are facing unexplained vacuum behaviour, clarity is not a nice to have. It is what allows teams to move forward with predictable performance and confidence. With the right structure and guidance, progress is simpler than it first appears.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

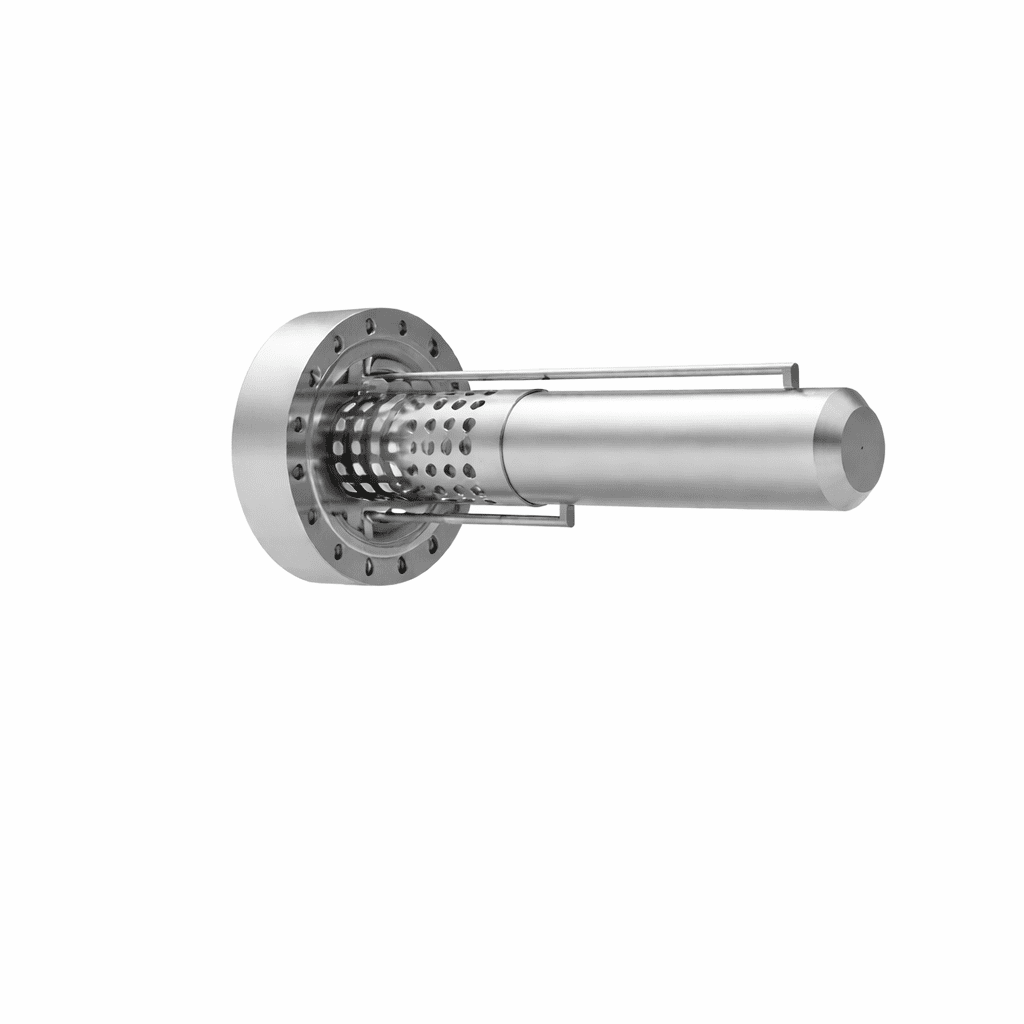

Start My RGA Selection High-Performance Residual Gas Analyzers or Learn more Residual Gas Analysis Guide for Vacuum Clarity