Reduce Risk and Gain Control in Your Vacuum Sputtering Process

Product news

You want a sputtering process that delivers stable deposition and films within specification on the first run, without costly retries or uncertainty.

The tension is that even a well-designed recipe can drift when target behaviour introduces variability you can’t see upfront.

The real issue is material uncertainty, grain size, purity, and thermal response inside the target, combined with the pressure to keep production moving, and it shouldn’t be this unpredictable.

The solution is a clear, practical plan: define what your process truly needs, confirm critical target specifications before manufacturing, and align material choice, purity, and bonding with your power density and application.

By addressing these variables early, you remove hidden risks instead of compensating for them later in the recipe.

This approach saves time, reduces scrap, and protects qualification schedules.

Once applied, deposition rates repeat, film properties stay in control, and unexpected arcing or downtime drops away.

You move forward with confidence, less stress, and the quiet status of someone whose process simply works.

Start by clarifying your target requirements and take the next step toward predictable sputtering performance.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

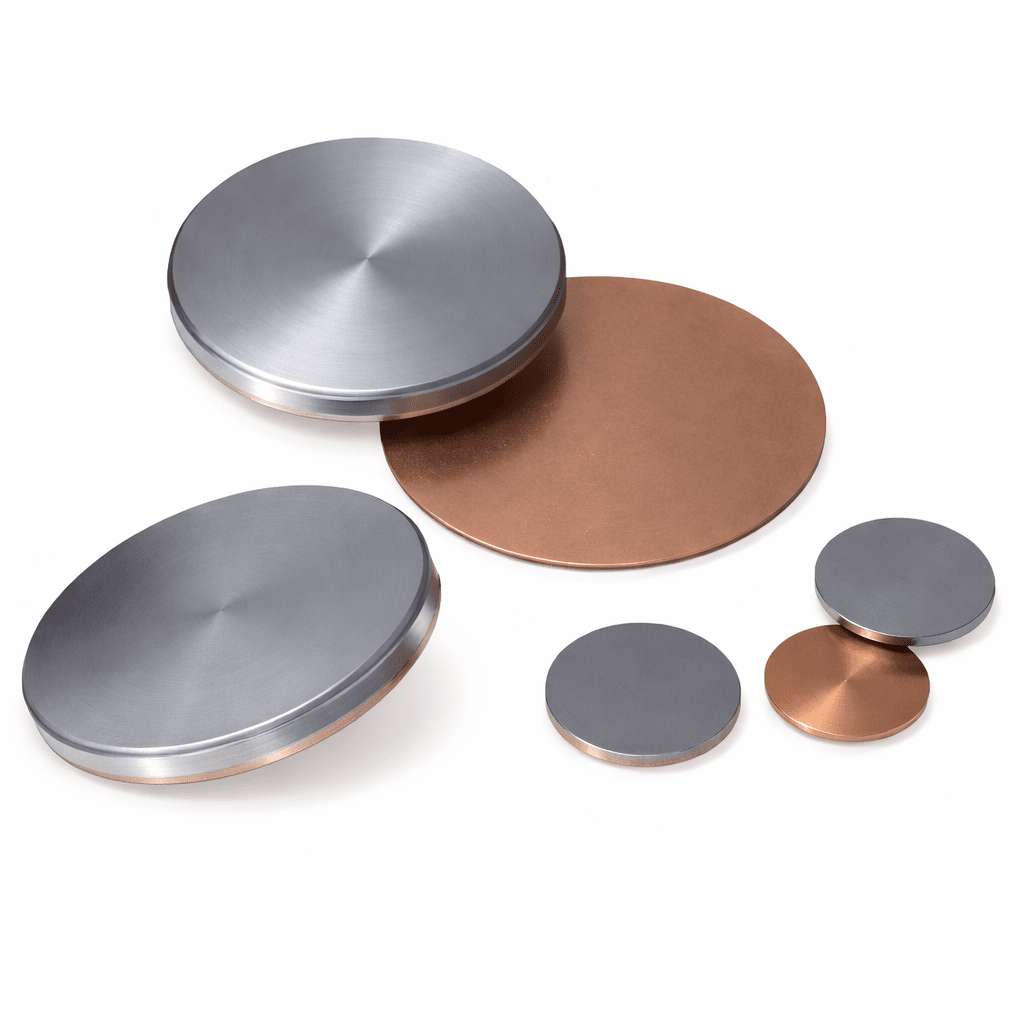

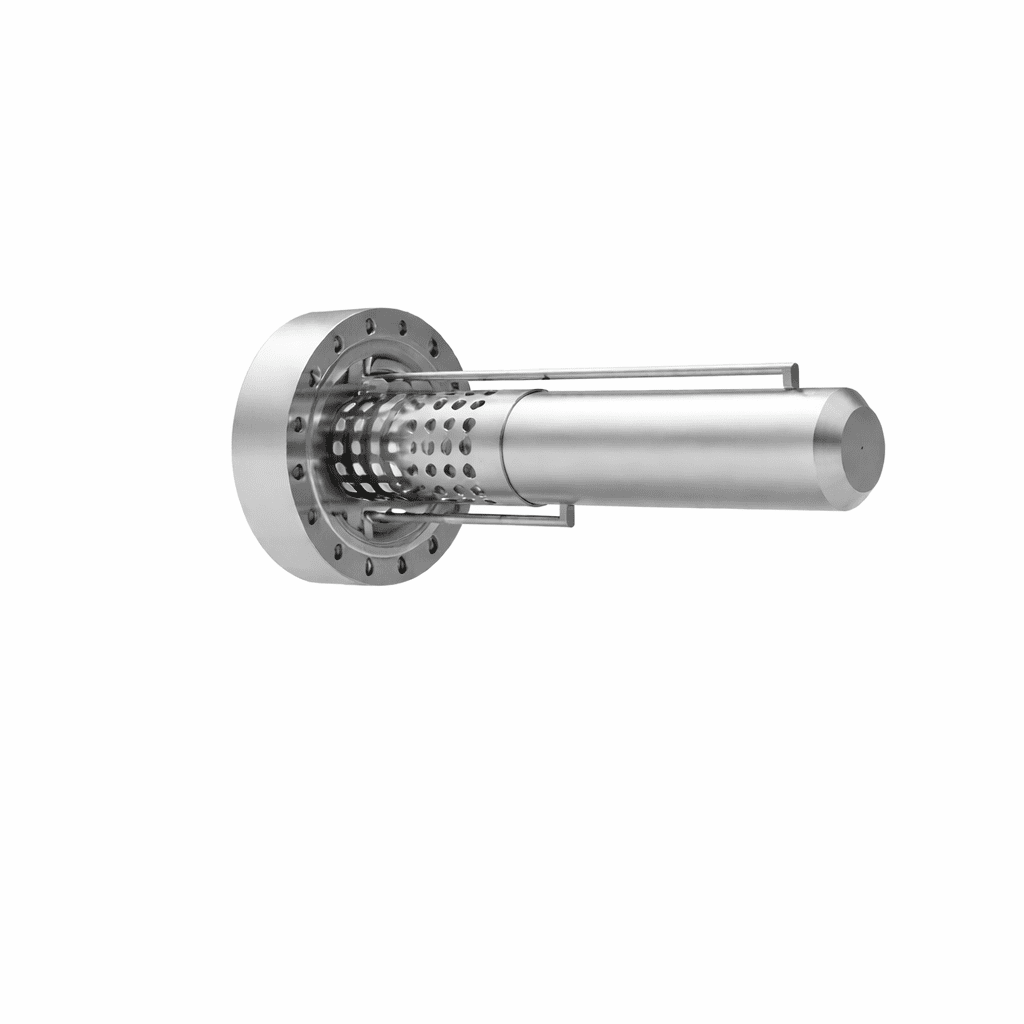

Request a Quote at info@tactile.tools or Start My Target SpecificationSputtering Targets | Planar & Rotary Thin Film Materials for PVD Deposition