Manufacturing & Services to Eliminate Sputtering Process Uncertainty

Expertise

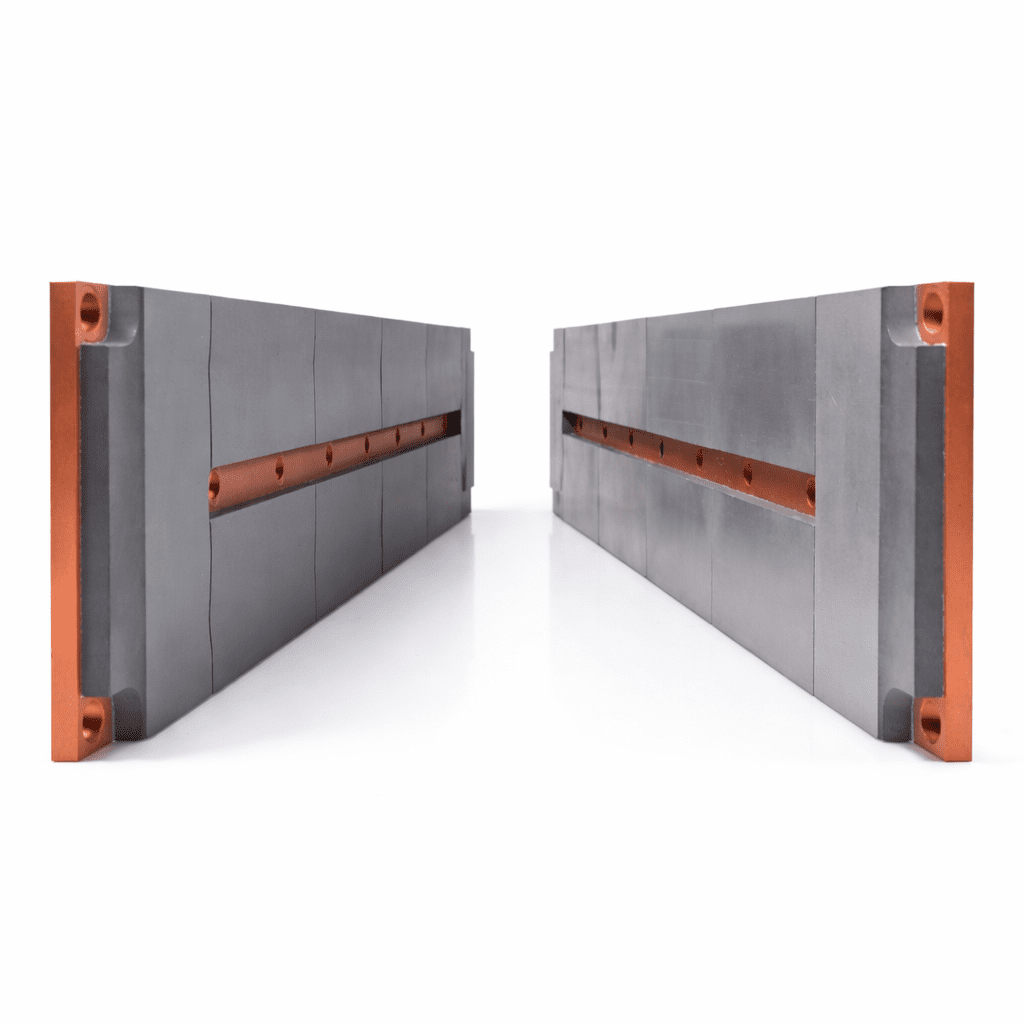

The issue is that material choice, manufacturing route, bonding, and backing plates are tightly linked, yet often handled separately, increasing risk and rework.

The real problem is fragmentation: different suppliers, unclear interfaces, and limited visibility into how targets are actually made, and it shouldn’t take extra effort to ensure compatibility and reliability.

The solution is a clear, integrated approach: select the right manufacturing method for your material, match the target and backing plate to your system, and validate everything through controlled production and testing.

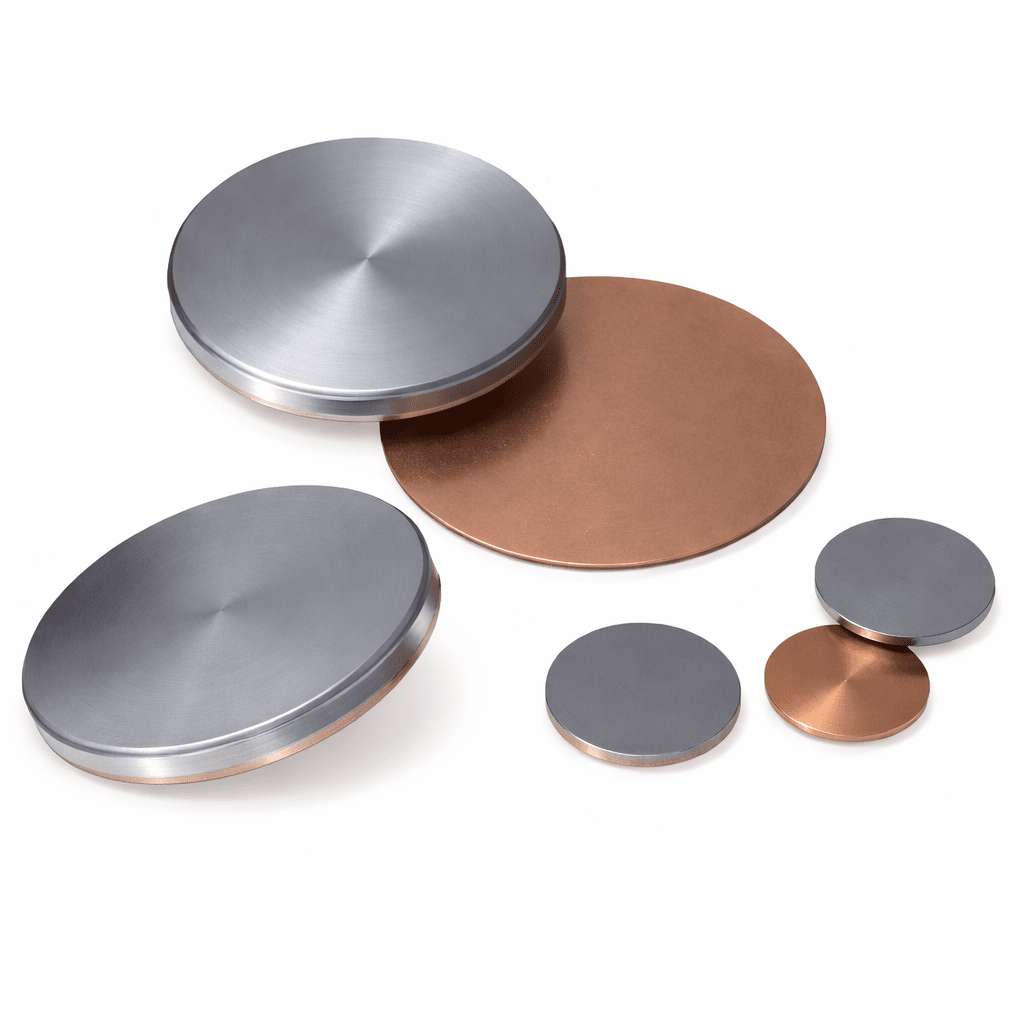

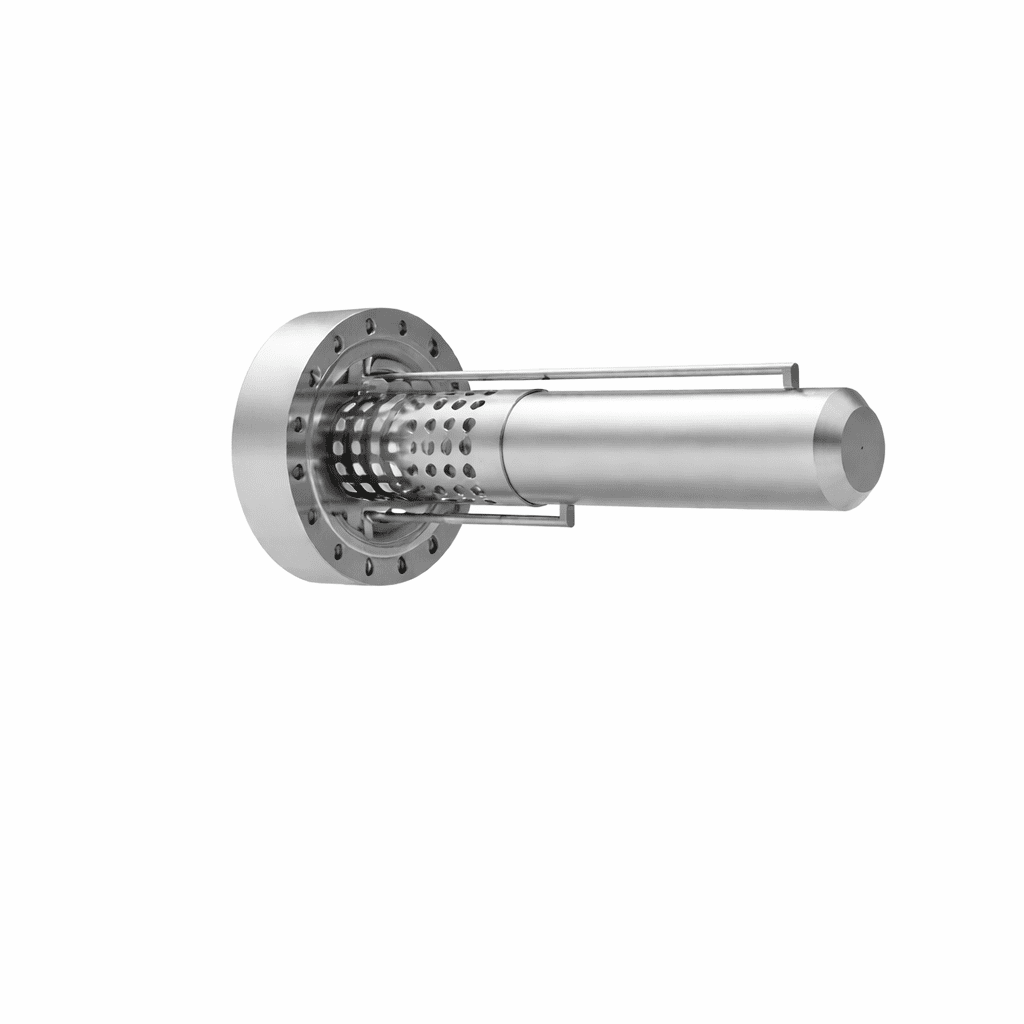

Advanced manufacturing, customized backing plates, and proven bonding options reduce thermal, mechanical, and process risk before installation.

Quality control, recycling, and lifecycle services keep performance stable while lowering long-term cost and waste.

Once in place, targets install smoothly, processes scale faster, and production runs with fewer surprises.

You gain confidence, shorter lead times, and the calm assurance that your sputtering setup is built to perform.

Take the next step by aligning manufacturing, services, and quality under one guided solution.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Request a Quote at info@tactile.tools or Start My Target SpecificationSputtering Targets | Planar & Rotary Thin Film Materials for PVD Deposition