Leak Types Explained & How to Test Them

Expertise

Leaks are frustrating because they are often invisible, inconsistent, and misunderstood.

- Is it a real leak, or outgassing, permeation, or a virtual leak?

- Is it small enough to ignore, or large enough to cause failures months later?

- Is your current test method even sensitive enough to detect the problem?

Without the right detection approach, leaks become quality defects, production delays, rework, safety risks, and costly recalls. Worse, vague results and jargon-heavy explanations leave teams unsure of what action to take.

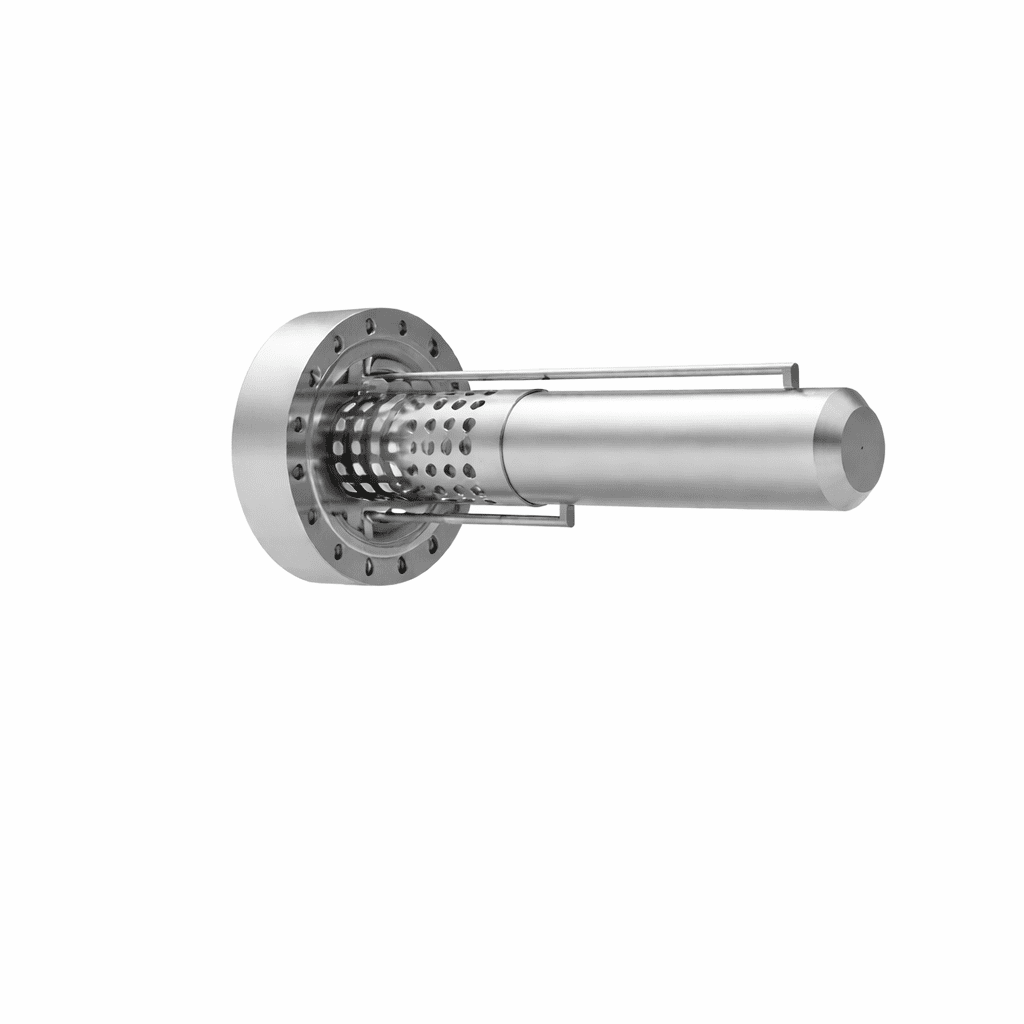

Our partners understand leaks at their most fundamental level, how they form, how they behave, and how they should be measured. With decades of experience in helium leak detection, vacuum technology, and semiconductor manufacturing environments, our partners provide clear tools, proven methods, and reliable results that teams can trust.

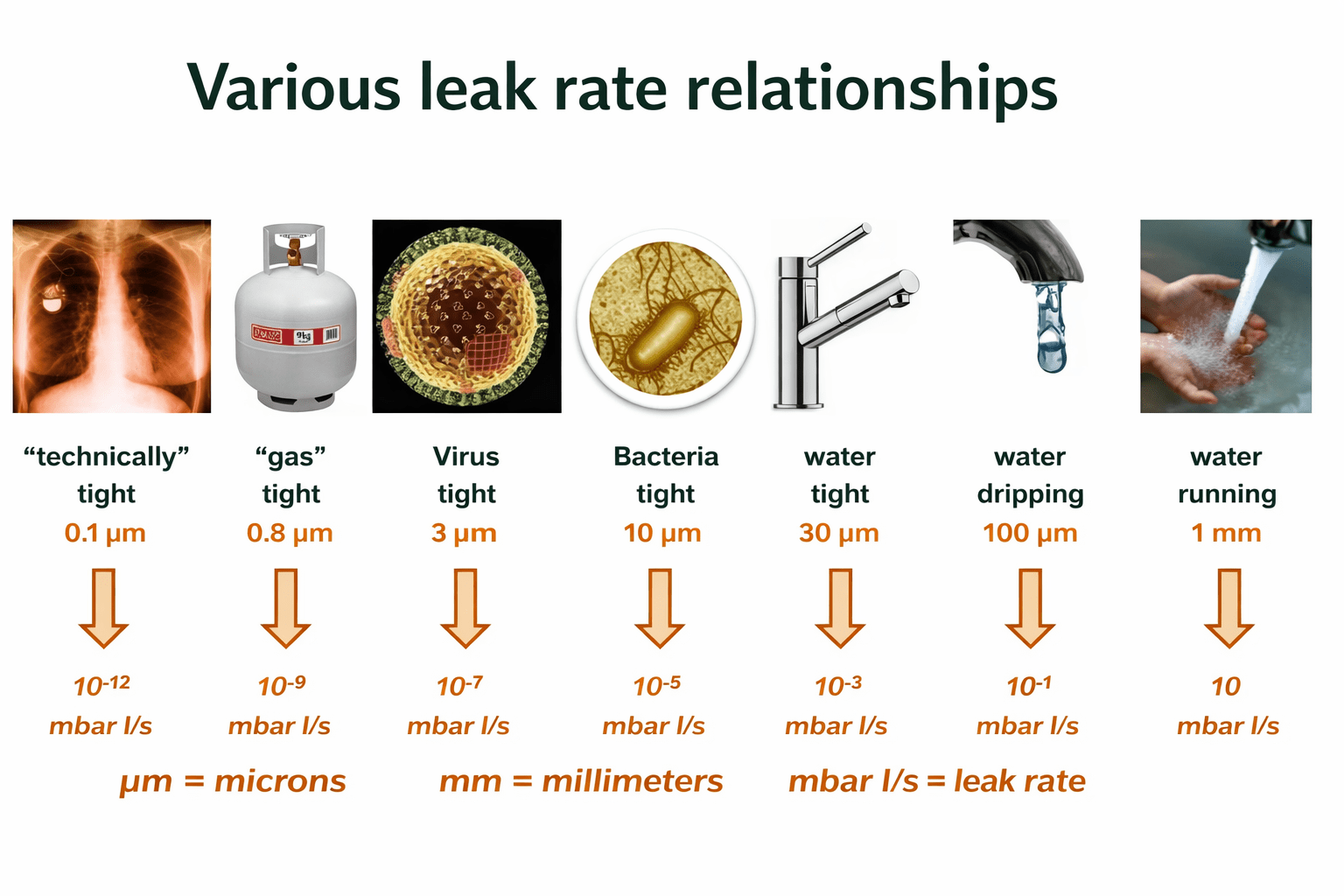

- Define the leak requirement: Identify whether you need water-tight, gas-tight, bacteria-tight, or ultra-high-vacuum integrity.

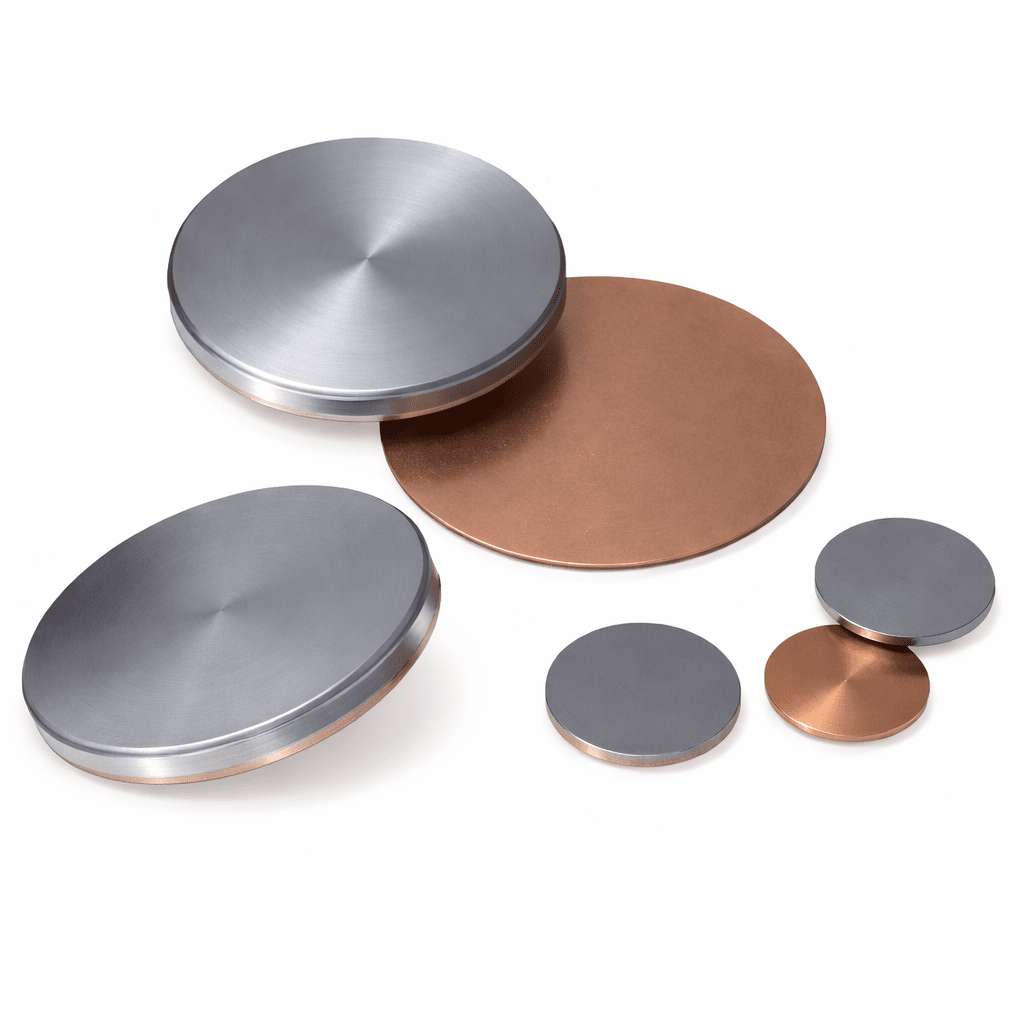

- Understand the leak type: Determine whether you’re dealing with pinhole, porosity, stringer, or apparent (virtual) leaks.

- Match the right test method: From pressure decay to helium vacuum accumulation, choose a method with the sensitivity your application truly demands.

- Accelerate and verify detection: Use intelligent tools and verification methods to shorten test cycles, reduce uncertainty, and eliminate false positives.

- Act with confidence: Make decisions based on measurable leak rates—not assumptions.

This approach removes risk, simplifies decision-making, and ensures your testing is aligned with real-world performance requirements.

After the right leak testing solution is in place, your world looks different. Production runs smoothly. Defects drop. Downtime shrinks. Audits become easier. Your team trusts the data, and your customers trust your products. Instead of chasing leaks, you’re building reliability, credibility, and long-term success, with confidence sealed in.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Start My Vacuum Leak Detection Reliable Leak Detection for Industrial & Research Use or Learn More Practical Vacuum Leak Detection Guide