Interview: RGA in Practice: An Engineer’s Story

Case Studies

Filip: To begin, can you tell us who you are, what you work on, and why residual gas analysis became relevant for you?

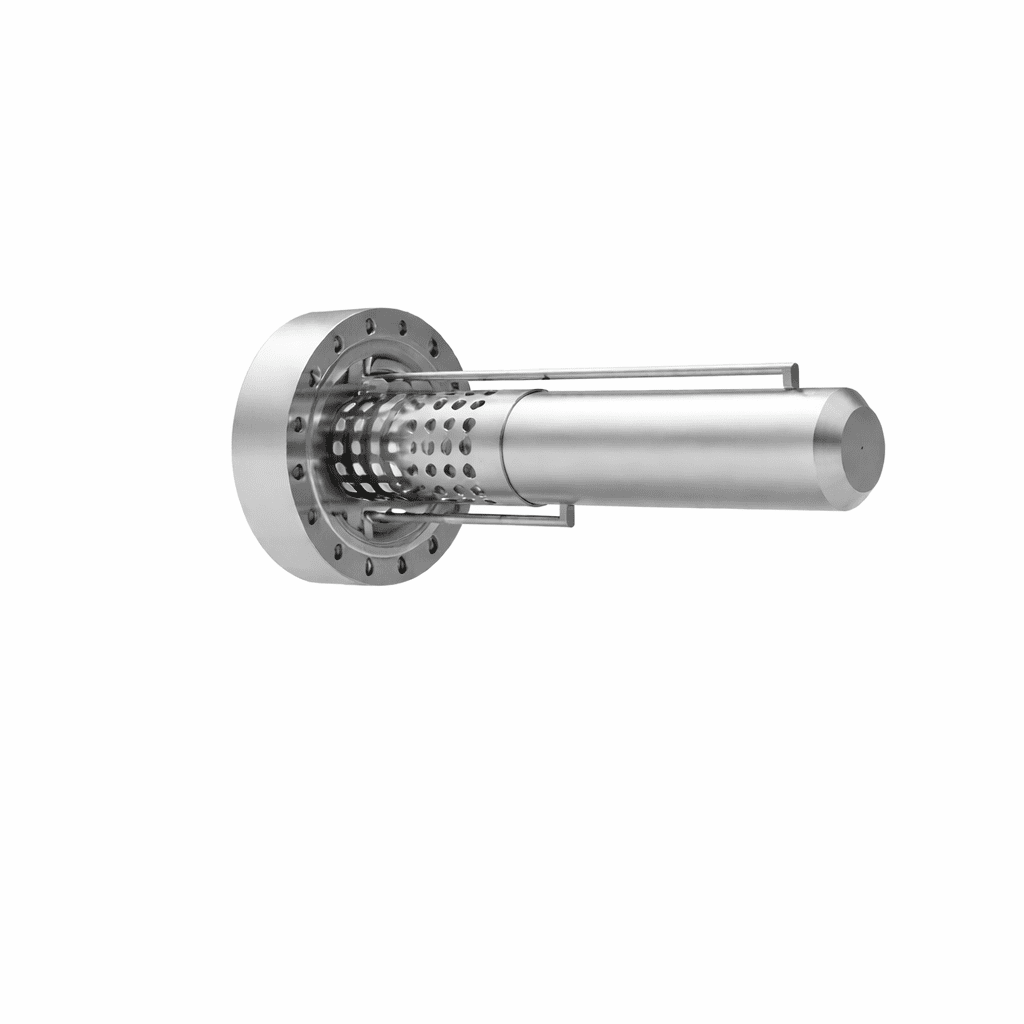

Engineer: I am a vacuum engineer working with high vacuum systems used for thin film deposition and materials research. This story takes place over the last few years in a shared research and production environment where uptime and repeatability matter. Residual gas analysis became important because pressure alone stopped giving us answers. We could reach our target pressure, but results were inconsistent, and that gap between what the gauge said and what the process delivered became impossible to ignore.

Filip: Before you had access to residual gas analysis, what did the situation look like day to day?

Engineer: The environment looked calm on the surface. The vacuum gauges were stable, pump down curves looked normal, and procedures were followed carefully. But underneath, it felt like working in a fog. When something went wrong, we could not tell if it was a leak, material outgassing, or contamination from a previous run. It was like driving at night with only the speedometer working. You know how fast you are going, but you cannot see the road.

Filip: What was the real challenge you were facing at that point?

Engineer: The challenge was uncertainty. We were accountable for results, but we did not have visibility into what gases were actually present in the chamber. Pressure readings treated all gases the same, even though water, hydrocarbons, and air have very different consequences. The risk was wasted experiments, lost production time, and long troubleshooting cycles. If we could not explain vacuum behaviour, we could not defend our decisions.

Filip: What happened next? How did you move forward?

Engineer: We started looking for a way to understand the vacuum instead of guessing. That is when residual gas analysis entered the conversation. The RGA itself was not presented as a magic solution. It was positioned as a guide, a tool that could show us what the pressure gauge could not. With support and clear explanations, we learned how to install it correctly, protect it from pressure excursions, and interpret the data in a practical way.

Filip: How did residual gas analysis change the situation?

Engineer: The change was immediate and very concrete. For the first time, we could see which gases were present and how they changed during pump down, bake out, and operation. Leaks looked different from outgassing. Water behaved differently from hydrocarbons. What used to feel mysterious became understandable. Before, we debated causes. After, we verified them. The RGA did not replace engineering judgment, but it gave that judgment something solid to stand on.

Filip: Can you describe the before and after in simple terms?

Engineer: Before, we relied on experience and instinct to explain problems that were not visible. After, we relied on evidence. Before, troubleshooting could take days. After, it often took minutes. Before, we hesitated before critical runs. After, we moved forward with confidence. The vacuum system went from being a black box to something we could actually read and trust.

Filip: Looking back, is there anything you would do differently?

Engineer: We would introduce residual gas analysis earlier. Not because every system needs the most advanced setup, but because even basic gas visibility changes how you think and work. We also learned the importance of matching the RGA to the application instead of overspecifying. The tool works best when it fits the real vacuum environment and workflow.

Filip: Why does this story matter for someone reading this today?

Engineer: Because many engineers are still in that early stage, where pressure looks fine but results are unstable. If that sounds familiar, this story is relevant. Residual gas analysis does not add complexity for its own sake. It removes uncertainty. If you are responsible for vacuum performance, seeing what is actually inside your system can change how you work, how fast you solve problems, and how confident you feel in your results.

Filip: What should the reader take away from this?

Engineer: If you recognize the frustration of unexplained vacuum behaviour, you are not alone. There is a practical, proven way to move from guessing to knowing. Residual gas analysis acts as a guide, helping you understand your system so you can make better decisions. Once you experience that clarity, it is hard to imagine working without it.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Start My RGA Selection High-Performance Residual Gas Analyzers or Learn more Residual Gas Analysis Guide for Vacuum Clarity