Stabilize Semiconductor Sputtering by Controlling the Target

Expertise

Most yield problems in semiconductor sputtering don’t start in the recipe.

They start in the target.

When deposition rates drift, via resistance changes, or films fall out of spec, the cost isn’t just rework.

It’s lost time. Extended qualification cycles. And uncertainty before every lot: “Is this a process issue, or a material one?”

We’ve seen this repeatedly in semiconductor PVD environments where margins are tight and variation isn’t tolerated.

The fix is simpler than most teams expect. Stabilize the process at the material level.

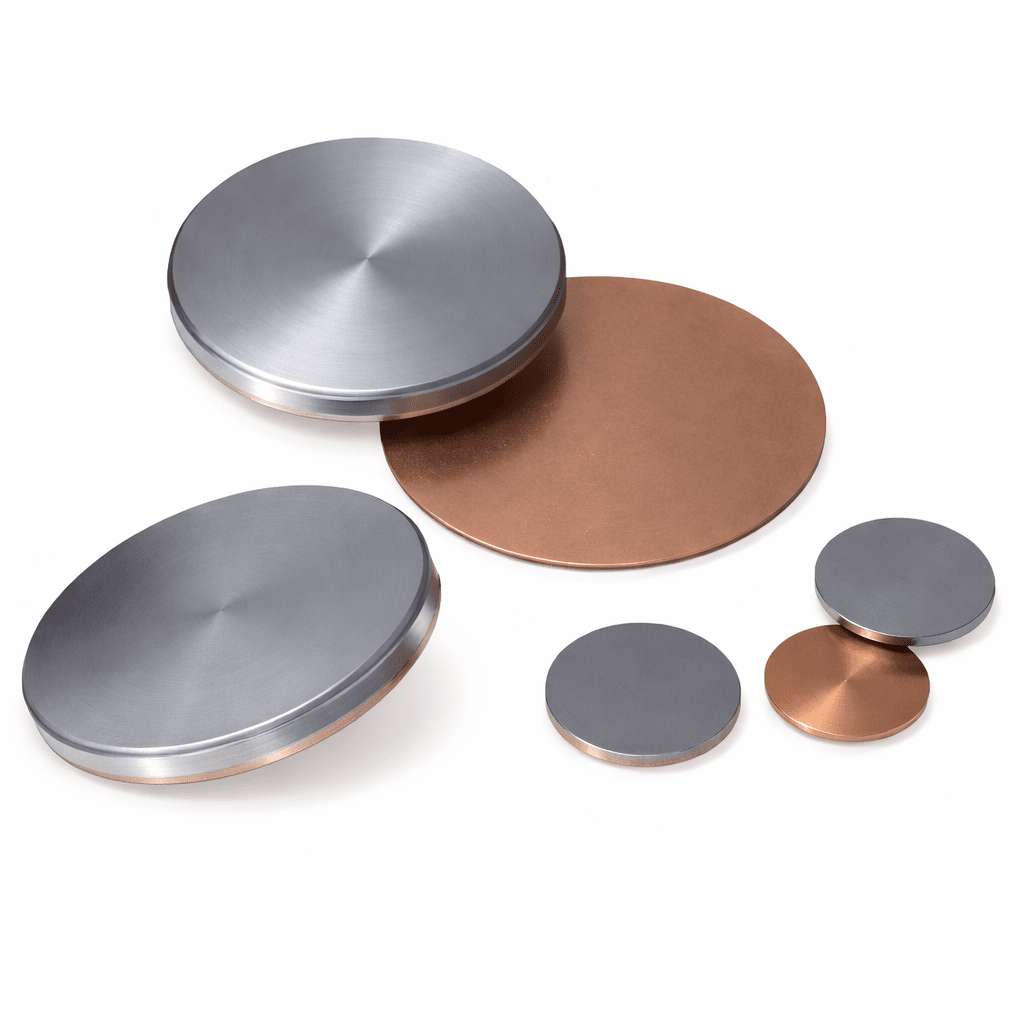

- Control target microstructure: Grain size and uniformity directly affect erosion, plasma stability, and film thickness control.

- Engineer purity beyond the datasheet: Trace impurities don’t average out, they transfer into resistivity, leakage, and long-term reliability.

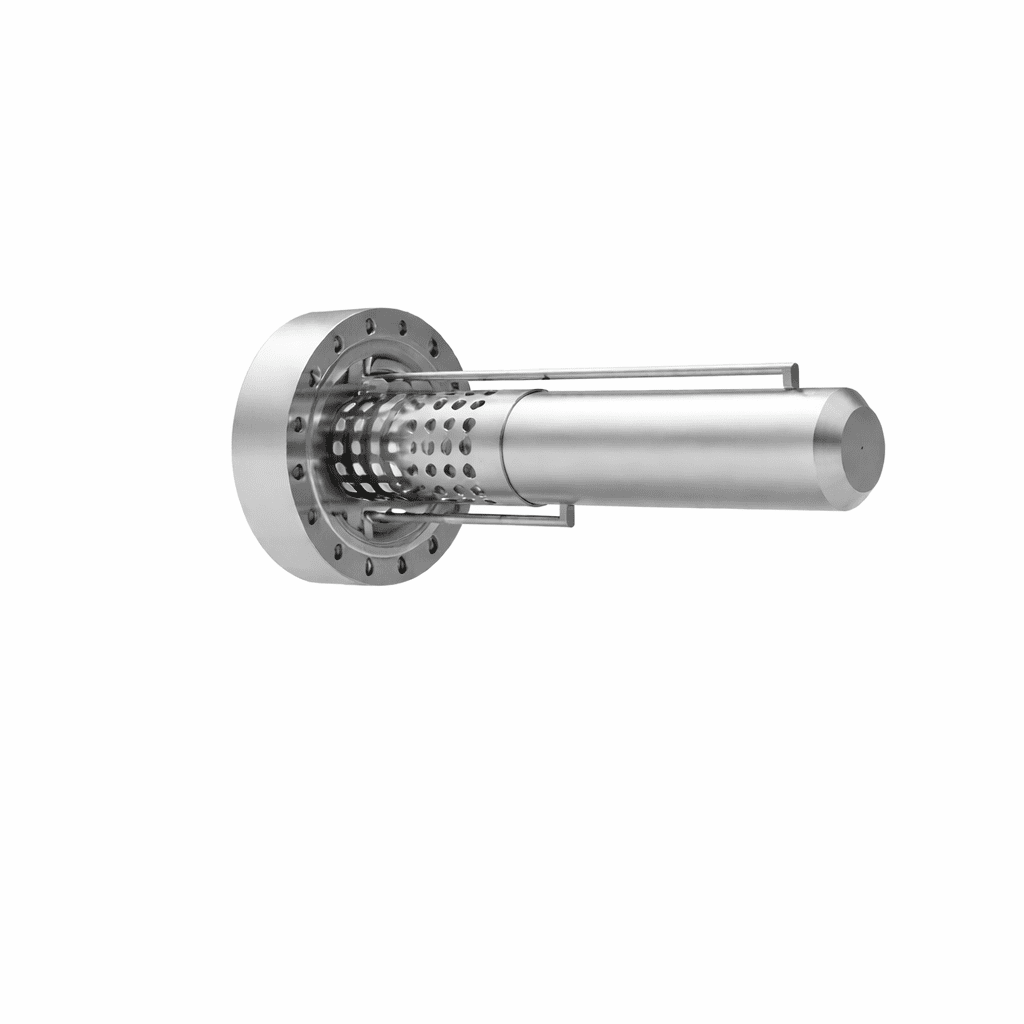

- Design for power density and thermal cycling: Bonding quality, backing plates, and CTE mismatch decide whether a target survives production reality.

In semiconductor sputtering, the target is not a component. It’s a process variable.

When this is done right, variability drops.

Deposition rates repeat run-to-run. Film thickness and properties stay inside control limits. Arcing and particle events decrease. Qualification cycles shorten instead of restarting.

Engineers stop compensating, and start trusting the process again.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Request a Quote at info@tactile.tools or Start My Target SpecificationSputtering Targets | Planar & Rotary Thin Film Materials for PVD Deposition