A Guide to Vacuum Leak Detection

Expertise

Vacuum engineers, equipment engineers, maintenance specialists, and lab or facility owners need confidence that a vacuum system is truly leak-tight. Specifically, they want:

- Clear confirmation that leaks are present or absent

- Results that are repeatable and defensible

- Leak tests that can be trusted across operators and time

- Fast resolution without chasing background signals or false positives

Leak detection is not just about finding leaks. It is about knowing whether a system can be trusted.

Leak detection often fails to deliver clear answers.

- Leak tests give inconsistent or ambiguous results

- Helium signals appear without clear interpretation

- Different tools give different answers

- Calibration status is unclear or outdated

- Time is lost repeating tests

- Systems still behave poorly after “passing” leak checks

Critical vacuum systems should not depend on interpretation or intuition. Leak detection should produce repeatable measurements that support decisions.

Gas Leak Detection as an Engineering Process.

Effective leak detection is method-driven, not tool-driven. The goal is to align:

- System characteristics

- Test objective

- Required sensitivity

- Measurement repeatability

Leak detection becomes reliable when method, setup, and interpretation are defined before testing begins.

Gas leak detection approaches

- Helium mass spectrometer testing: Used for quantitative HV/UHV leak rate measurement when acceptance criteria matter.

- Sniffer leak detection Used for locating leak points quickly on pressurized or charged systems.

- Tracer gas spray methods Used to control helium delivery and reduce background effects.

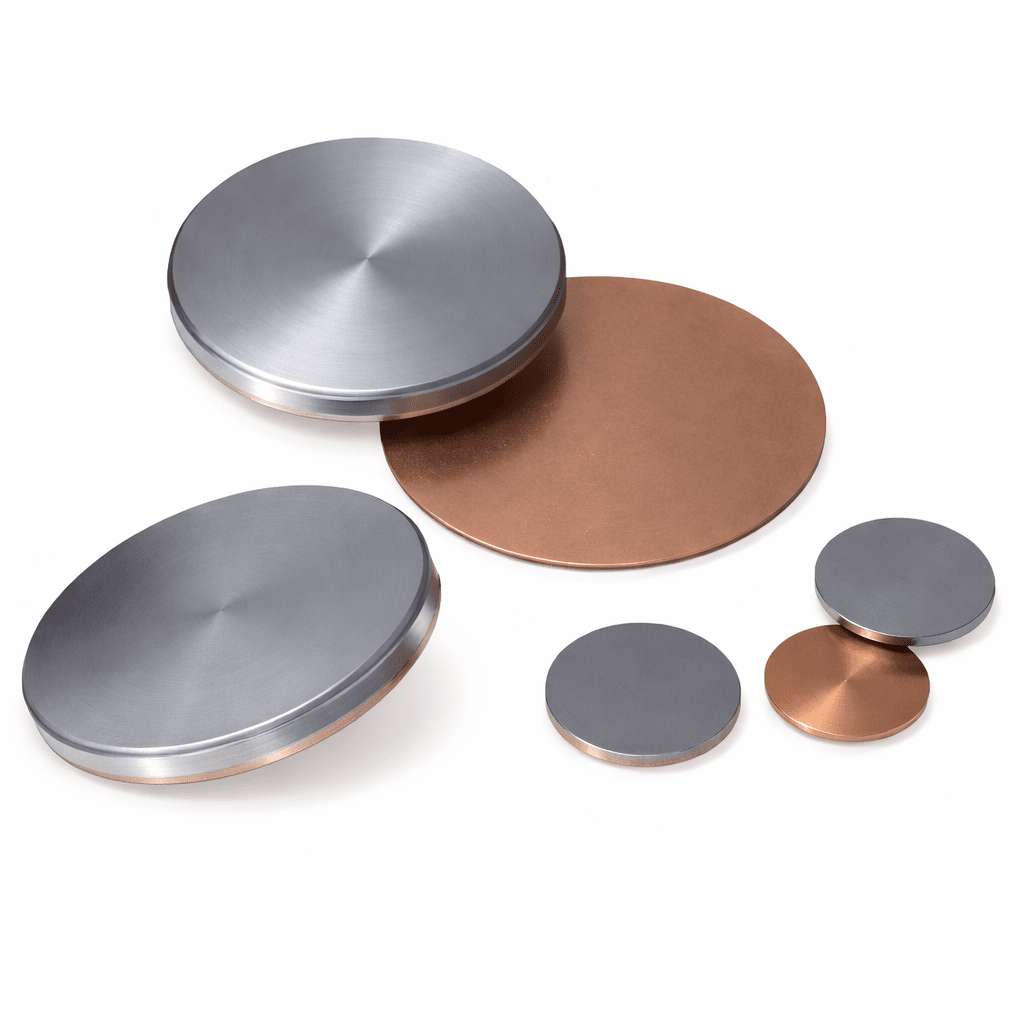

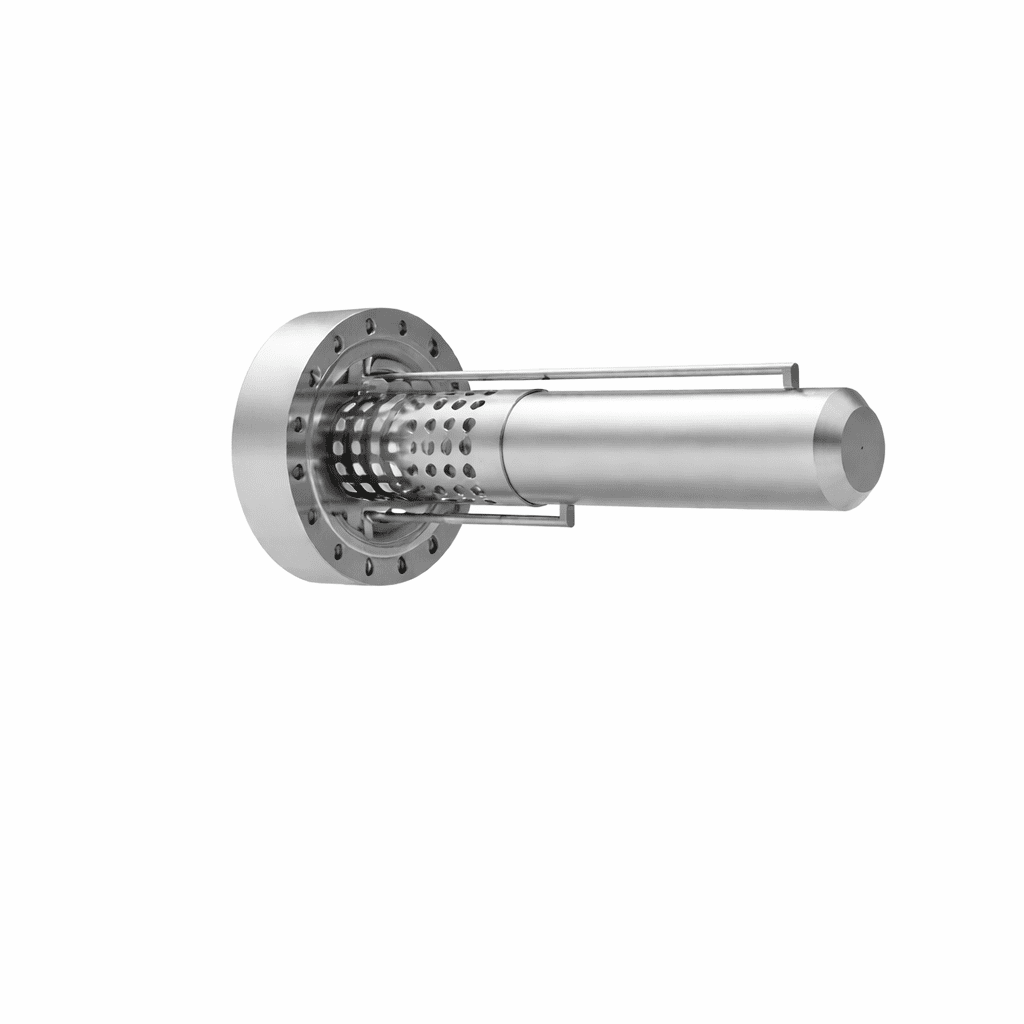

- Calibration and reference leaks Used to verify detector response and measurement validity.

No single method is correct for all systems. The application defines the approach.

The Plan: A Simple, Repeatable Framework

Step 1: Vacuum Environment

- Operating vacuum level (rough, HV, UHV)

- System volume and pumping speed

- Cleanliness or contamination sensitivity

These factors directly affect achievable sensitivity and background behavior.

Step 2: Objective

- Confirm leak-tightness or locate a leak

- Quantitative leak rate or qualitative confirmation

- Purpose: qualification, maintenance, troubleshooting, or production

A test without a defined objective will produce ambiguous results.

Step 3: Match the Detection Method

- Mass spectrometer testing for quantitative confidence

- Sniffer methods for fast localization

- Tracer gas tools for controlled application

- Reference leaks for validation

Avoid selecting instruments before defining the method.

Step 4: Make the Test Repeatable

- Defined setup and operating procedure

- Verified calibration or reference check

- Control of background helium and environment

- Clear pass/fail criteria established in advance

Repeatability turns leak detection from troubleshooting into measurement.

If leak detection results are unclear, the next step is to clarify the method, not repeat the test. Practical next actions:

- Review whether the test method matches the system and objective

- Verify detector calibration and sensitivity limits

- Distinguish background signals from true leaks

- Align acceptance criteria with system requirements

Successful leak detection produces clear outcomes.

- Real leaks are identified quickly

- Background signals are understood and controlled

- Results are repeatable across operators

- Systems that pass leak tests behave accordingly

It means confidence in the test result instead of doubt. Repeated testing is reduced, saving time and effort. Stress before system qualification or operation is lower. Trust is restored in both the vacuum system and the measurement. Leak detection supports clear decisions rather than creating uncertainty. Success is not finding a leak, but knowing whether one exists.

Start My Vacuum Leak Detection Reliable Leak Detection for Industrial & Research Use or Learn more Tactile | Tools for Advanced Clean Tech - Advice