A Guide to Residual Gas Analysis: Making Vacuum Visible

Expertise

Semiconductor engineers and research scientists work in environments where vacuum quality directly affects yield, data validity, and process stability. What they need is clear visibility into which gases are present inside their vacuum systems.

You want to identify gas species, not rely on total pressure alone, and distinguish leaks from outgassing and contamination. You want to confirm pump down and bake out endpoints with confidence.

Pressure measurement alone is not enough in high and ultra-high vacuum systems. A pressure gauge reports how much gas is present, but not what kind of gas it is. As a result, different problems look identical. A real leak, material outgassing, pump back streaming, or residual process gases can all produce similar pressure readings.

This leads to uncertainty during troubleshooting. Bake out endpoints are often chosen by time rather than data. Short contamination events are missed. Engineers spend time addressing symptoms instead of causes. The vacuum system may look acceptable but behaves unpredictably.

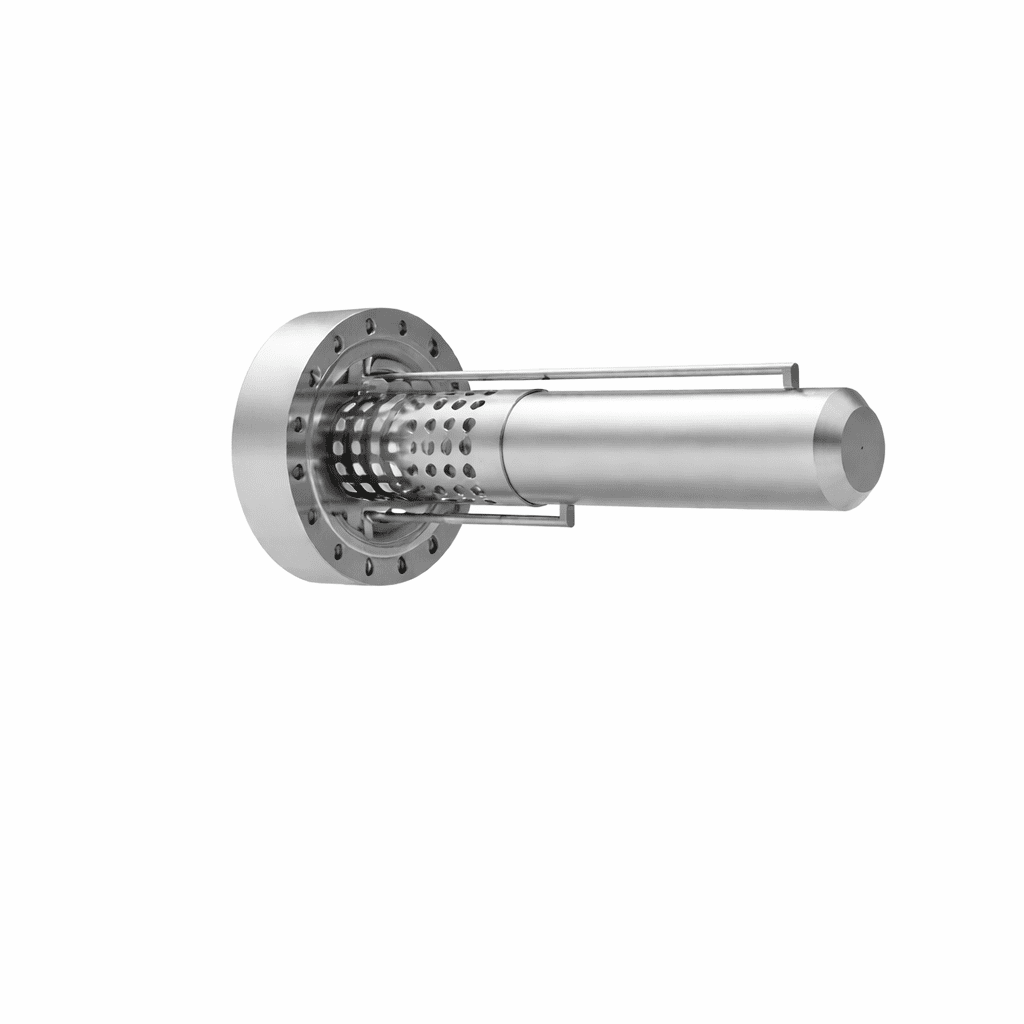

Residual Gas Analysis (RGA) provides gas composition information that pressure gauges cannot. An RGA measures partial pressures of individual gas species. This allows users to see which gases are present and how they change over time. With this information, vacuum behaviour becomes understandable rather than assumed.

RGA does not replace good engineering practices. It supports them by providing visibility. It is a technology neutral diagnostic tool used across semiconductor manufacturing, research laboratories, aerospace, energy, and industrial vacuum processing. The role of RGA is to remove uncertainty, not to add complexity.

A structured approach makes RGA selection and use straightforward.

- Step 1: Objective

Leak identification, outgassing analysis, bake out or pump down confirmation, contamination detection, process gas monitoring, or research analysis.

- Step 2: Vacuum Environment

Identify base pressure, operating pressure, pressure excursions, and whether the system is static or has flowing gases. This ensures compatibility and protects the analyzer.

- Step 3: Relevant Gases

List expected background gases, process gases, and potential contaminants such as water, hydrocarbons, or reactive species. The RGA must be suitable for the chemistry involved.

- Step 4: Performance Requirements

Select the appropriate mass range, sensitivity, and scan speed based on what needs to be detected. Avoid unnecessary performance while ensuring critical gases are visible.

- Step 5: Ensure Practical Use

Consider how data will be viewed, logged, and interpreted. Confirm integration needs, maintenance expectations, and suitability for the operating environment.

With RGA in place, the vacuum system is no longer untransparent. Gas species are identified clearly. Leaks, outgassing, and contamination are separated. Pump down and bake out endpoints are confirmed using composition data. Issues are detected earlier and addressed with confidence.

Decisions are supported by evidence, not assumptions. Troubleshooting becomes faster and more focused. Vacuum quality becomes measurable and defensible. Pressure indicates quantity. RGA provides composition. Together, they enable controlled and predictable vacuum performance.

Tactile purpose is to remove uncertainty from vacuum systems, helping engineers move from hidden instability to predictable performance, calm operations, and confidence in their results.

Start My RGA Selection High-Performance Residual Gas Analyzers or Learn more Tactile | Tools for Advanced Clean Tech - Advice